MF2904/IR

Installation

6

9/25/08

Bradley

Corporation

• 215-752 Rev. U EN 08-023

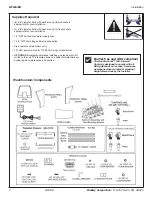

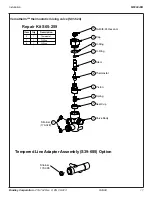

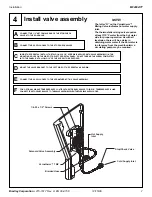

Braided Hose

Cold Supply Inlet

Hot Supply

Inlet

Stop/Check Valve

Vernatherm™ TMV

Solenoid Valve Assembly

1/4-20 x 1/2" Screws

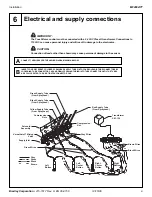

#10-24 x 3/4" OVAL PHILLIPS

HEAD SCREW

STRAINER

DRAIN SPUD

WASHFOUNTAIN BOWL

SPUD LOCKNUT

(PART OF SPUD)

WASHER (PART OF SPUD)

8

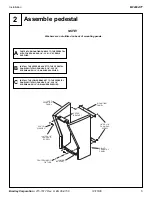

Drain Assembly

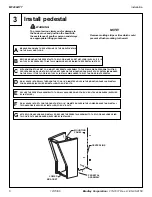

Install the optional soap system following

the instructions outlined in manual 215-1136

provided with the soap system.

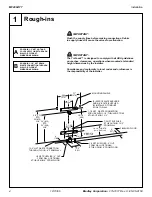

A

Connect the 1/2" NPT female

end of the stop/check valves

to the rough-ins. Connect

the supply hoses to the stop/

check valves.

7

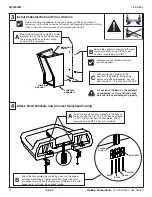

Install Solenoid Assembly Fixture and Supply Connections

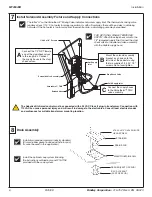

The letter “H" on the Vernatherm™ Mixing Valve indicates hot water supply inlet. The thermostatic mixing valve

requires at least 115° F hot water for proper operation. As with all lavatories, there will be a delay in obtaining

hot water. If the hot water is too far away from the washfountain, a circulating pump may be required.

B

Mount the solenoid assembly

bracket as shown onto the

left side of the pedestal using

the two supplied 1/2-20 X 1/2"

screws. Do not overtighten.

C

Connect the supply hoses

to the Vernatherm™ TMV

valve assembly.

FOR OPTIONAL SINGLE TEMPERED

SUPPLY: Attach the stop/check valve to the

1/2" tempered supply line. Connect the stop/

check valve to the solenoid valve assembly

with the fl exible supply hose.

The Adaptive® Infrared control must be connected with a 24 VAC Class II plug-in transformer. Connection with

110 VAC can cause personal injury and will result in damage to the electronics. Consult local electrical codes

and ordinances for suitable transformer mounting location.

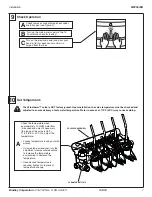

Install drain spud per common industry standard.

(Discard rubber gasket included with drain spud;

it cannot be used in this application.)