MF2904/TT

Installation

12

12/15/06

Bradley Corporation • 215-1617 Rev. A; EN 06-915C

Solenoid Valve troubleshooting

CAUTION:

Turn off water supplies to unit before troubleshooting.

Problem:

An individual operating station fails to shut off and drips.

Cause:

There is debris trapped between the diaphragm and the valve seat.

Solution:

Remove debris between diaphragm and the valve seat.

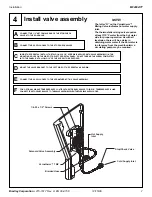

1. Remove the three #8 Phillips-head screws that hold the solenoid valve assembly together. Be

careful not to lose the armature or spring (see page 13).

2. Remove the diaphragm. Remove any particles that have been trapped between the diaphragm and

the valve seat. Rinse off the diaphragm and inspect for damage. Make sure the center orifice and

both small side orifices are open.

3. Reassemble in reverse order, being careful not to overtighten the Phillips-head screws or you may

crack the plastic valve body. Tighten until the armature plate makes contact with the plastic body.

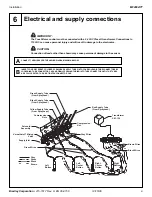

4. Reconnect the wiring per diagram on page 9.

Problem:

An individual operating station fails to turn on.

Cause:

A failed coil for the valve or loose electrical connection to the terminal.

Solution:

Test the station to determine cause.

1. Disconnect the wires from the coil of an adjacent valve. Disconnect the wires from the problem

valve and reconnect to the adjacent valve.

2. Turn on electrical and water supplies to the unit. Pass your hand in front of the sensor of the

problem station, and the adjacent station should turn on.

If the adjacent station turns on and cycles normally, replace the coil on the problem valve.

If the adjacent valve fails to turn on, inspect the wires from the sensor cable and do the following:

• make sure there are no breaks and that the fully insulated disconnect terminals are firmly

crimped in place;

• turn off the electrical and water supplies;

• reconnect to the adjacent valve and turn on the water supplies to the unit;

• pass your hand in front of the sensor. If the station still fails to turn on, replace the sensor.