!

The appliance must be installed by a qualified person in

compliance with the instructions provided.

!

Wear gloves when carrying out installation and maintenance

operations.

If the supply cord is damaged, it must be replaced by the manufacturer,

its service agent or similarly qualified persons in order to avoid a hazard.

Warning: Failure to install the screws or fixing device in accordance with

these instructions may result in electrical hazards.

The hood can look different to that illustrated in the drawings in this booklet.

The instructions for use, maintenance and installation, however, remain the

same.

AIR VENT

(for ducting versions)

!

Prepare the hole and the air vent duct (150 mm diameter).

!

Use a duct of the minimum indispensible length.

!

Use a duct with as few elbows as possible (maximum elbow angle: 90°).

!

Avoid drastic changes in the duct cross-section.

!

Use a duct with an as smooth as possible inside.

!

The duct must be made of certified material.

!

Do not connect the hood to smoke exhaust ducts for the products of

combustion (boilers, fireplaces, stoves, etc).

!

For the air vents comply with the provisions laid down by the competent

authorities.

In addition, the air must not be evacuated through a hole in the wall

unless specifically intended for this purpose.

!

Fit air intakes in the room to prevent the hood from creating a negative

pressure in the room (which must not exceed 0.04 mbar); if the hood is

used at the same time as non-electrical equipment (gas-, oil- and

charcoal-fired stoves, etc.) the exhaust gas may be sucked in by the

heat source.

FILTERING OR DUCTING VERSION ?

The hood may be in filtering or in ducting version. Decide from the outset

which type is to be installed.

For better efficiency, we recommend installing the hood in the ducting

version (if possible).

Ducting version

The hood purifies the air and evacuates it to the outside through an

exhaust duct (diameter 150 mm).

Filtering version

The hood purifies the air and recycles the clean air back into the room. For

this version, the following are required: 1 air baffle, 1 reducer, 1 charcoal

filter. The upper flue air evacuation slots must be positioned at the top.

The 4th speed (intensive) is automatically lowered to 3rd speed after 5

minutes of operation to optimise energy consumption; in hoods with

voltage 120V/60Hz this function is not active and the 4th speed is

indicated by the letter b (Booster).

- If the hood is left on (lights and/or motor), after 10 hours in the absence

of commands from the user, it will automatically switch to OFF condition

with all services switched off. In hoods with voltage 120V/60Hz this

function is not active.

- The Buzzer emits a “beep” each time that a command is set from the

keyboard or remote control (optional).

- In the event of interruption of power during the hood, if you restore

the hood in the OFF state, then the engine must be reactivate manually.

CONTROLS

Controls of Fig. 32

Button A = turns the lights on/off.

Button B = turns the TIMER on/off: press once to turn the timer on,

therefore, after 5 minutes, the motor cuts out (at the same time the

selected speed blinks on the display); the timer remains on if the motor

speed is changed.

Display C = - indicates the selected motor speed (from 1 to 4); - indicates

Timer On when the number blinks; - indicates Filter Alarm when the central

segments is on or blinking.

Button D = makes the motor work (at the last speed selected); pushing the

button again, the speeds of the motor are sequentially selected from 1 to 4;

keeping this button pressed for about 2 seconds shuts down the motor.

Button R = resets the grease filters or charcoal filters; when the filter alarm

appears (i.e. when the central segment on the display goes on), the grease

filters must be cleaned (30 hours of operation); when the central segment

starts blinking, the grease filters must be cleaned and the charcoal filters

replaced (120 hours of operation). Obviously, if the hood is not a filtering

model and does not have a charcoal filter, clean the grease filters both

when the central segment goes on and when it starts blinking. The filter

alarm can be seen when the motor is off and for about 30 seconds. To

reset the hour counter, keep the button pressed for 2 seconds while the

alarm can be seen.

MAINTENANCE

!

Before cleaning or maintenance cut the power.

Cleaning the hood

WHEN TO CLEAN IT: clean it at least every 2 months to prevent the risk

of fire.

EXTERNAL CLEANING: use a cloth moistened in lukewarm water and

neutral detergent (for painted hoods); use specific products for steel,

copper or brass hoods.

INTERNAL CLEANING: use a cloth (or brush) soaked in denatured ethyl

alcohol.

WHAT NOT TO DO: do not use abrasive or corrosive products (e.g. metal

sponges, brushes, too hard brushes, very aggressive detergents, etc.)

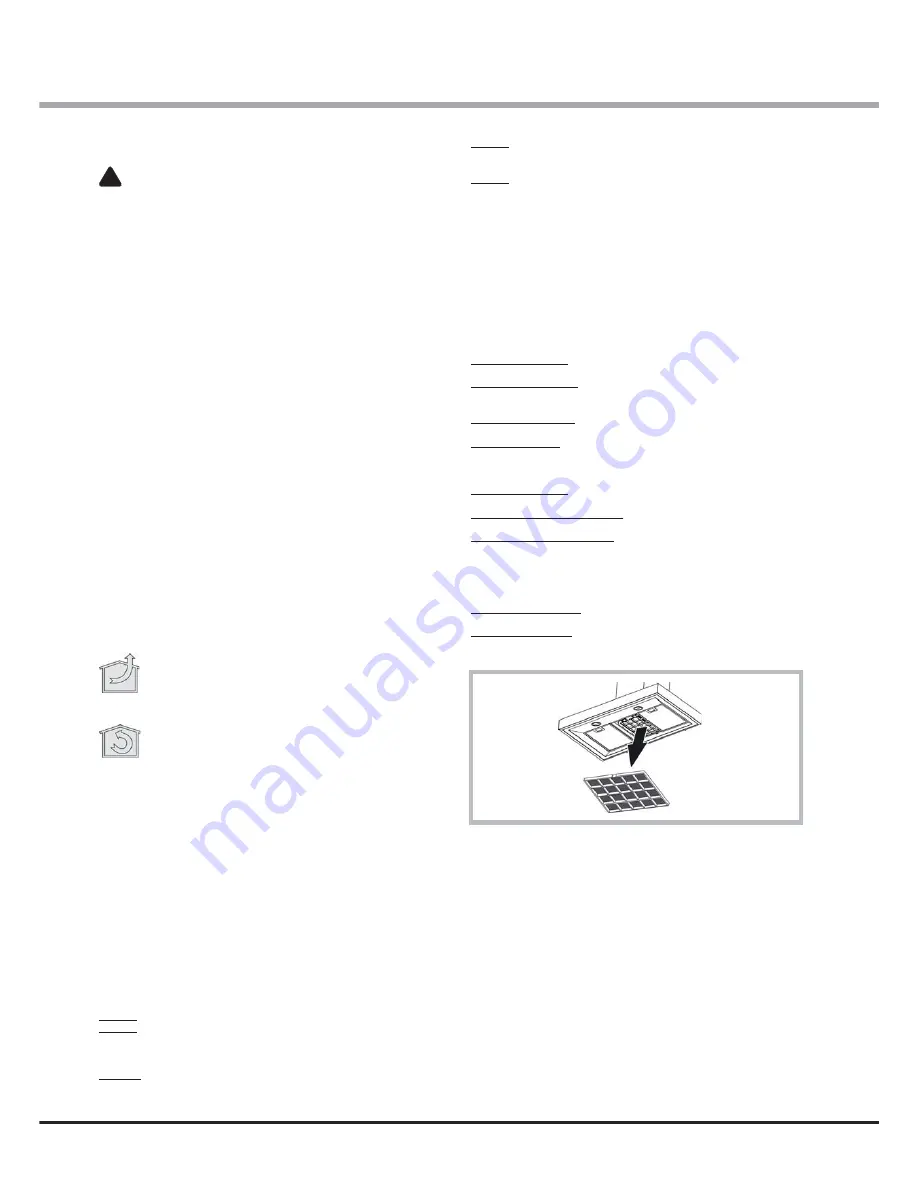

Cleaning the grease filters

WHEN TO CLEAN IT: clean it at least every 2 months to prevent the risk

of fire, in according to use.

HOW TO REMOVE THE FILTERS: push the catch near the handle towards

the rear of the hood and pull the filter downwards

HOW TO CLEAN THE FILTERS: hand wash or in the dishwasher using a

neutral detergent. If washing in the dishwasher, possible discoloration of the

filters does not in any way compromise their functioning.

Replacing the charcoal filter

(for filtering version only)

WHEN TO REPLACE IT: replace it at least every 6 months, in according to

use.

HOW TO REMOVE IT: If using the hood in the filtering version, the

charcoal filter will have to be replaced. To switch off, pull the latch inward

and rotate the filter downwards.

Lighting

If the light spot is damaged, it must be replaced only by the manufacturer,

its service agent or similarly qualified persons in order to avoid a hazard.

Summary of Contents for AD1521X

Page 2: ......

Page 3: ......

Page 4: ......

Page 5: ......

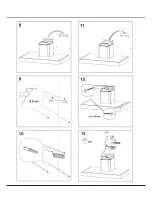

Page 6: ...13 ...

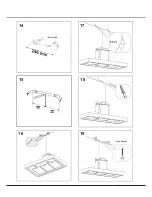

Page 7: ...15 14 16 18 17 19 ...

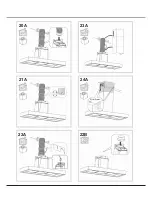

Page 8: ...21A 20A 22A 24A 23A 22B ...

Page 9: ...24B 23B 25B 27B 26B 28B ...

Page 10: ...32 A B C D R 30B 29B 31B ...

Page 48: ...04308485 1 ...