13

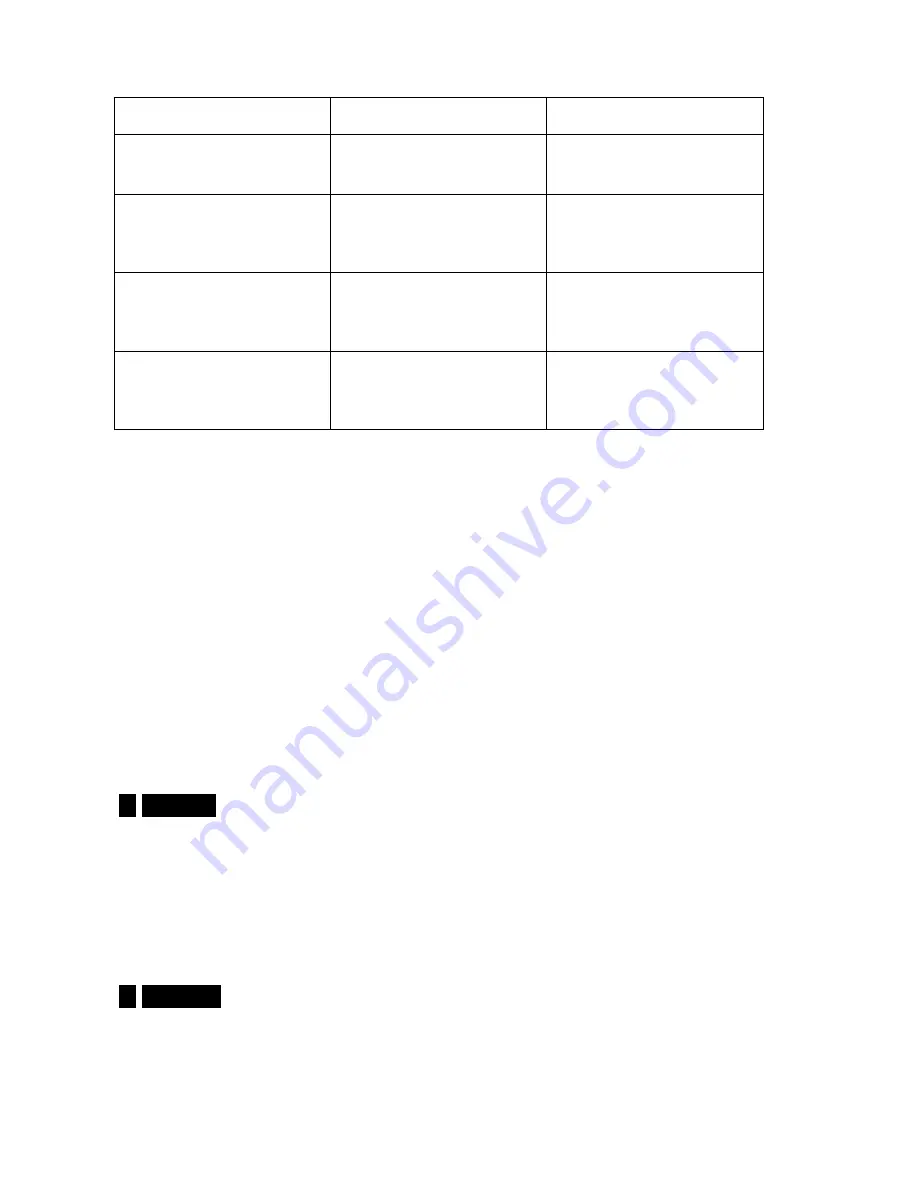

9 TROUBLE-SHOOTING

Situation

Cause of trouble

Remedy

1. Jack does not hold firmly

the load.

Brake slipping.

Brake adjusting or repair

according to the chapter

„Maintenance“.

2. Jack jacks up heavily or

does not raise the load.

(1) Jack is overloaded.

(2) Damaged geared

transmission.

(1) Lower the load weight

to the value of the safe

working load.

(2) Repair of the jack

3. Jack emits the special

noise.

Insufficiently greased

geared transmission.

Carry out the lubrication of

the geared transmissions

by grease.

4. Characteristic sound is

not heard when snapping

the pawls to dents of

ratchet.

Malfunction of pawls.

Rust, impurities, broken

spring.

Clean up, replace the

spring.

10 GREASING

10.1 GENERALLY

Before application of the grease remove old grease, clean up components with grease

solvent and apply new grease. Use grease specified by the producer.

Lifters type HZ are equipped with a lubrication plug on the cover of the gear transfer. We

recommend regular lubrication of the gear mechanism at least once every 6 months.

10.2 JACK MECHANISM

Throw up the unloaded jack to the maximum position. Grease with PM-A2 vaseline or its

equivalent the ridge bar and lower down the jack.

Lifters type Rack lifter are to be lubricated with a lubrication press through the lubrication

plug.

Grease all slipping or moveable surfaces on the crank of the jack.

! NOTICE

Imperfect maintenance and insufficient greasing can cause a serious accident.

ALWAYS

grease more often in corrosive environment (salt water, oceanic climate,

acids etc.) than in ordinary circumstances.

11 MAINTENANCE

11.1 SECURITY PRINCIPLES

! Warning

Only qualified persons (service organizations), trained in safety and maintenance of

the jacks, can carry out maintenance and professional inspections.

ALWAYS

use entirely components supplied by the producer.