14

It is not permitted to carry out repairs and maintenance in other way than

specified by the producer. It means namely the forbiddance of using unoriginal

spare parts or carrying out of changes on the product without the approval of the

producer.

ALWAYS

test jack function after carrying out the maintenance.

ALWAYS

mark disabled or repaired jack with appropriate inscription (i.e.

„OUT OF

OPERATION“

).

NEVER

carry out maintenance if there is the load on the jack.

NEVER

work with the jack that is under repair!

11.2 REPLACEMENT OF BRAKE INSERTS AND BRAKE ADJUSTING

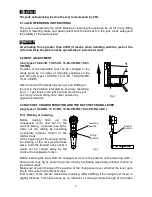

11.2.1 Brake disassembly (fig. 6)

Demount the (crank or crank-lever) from the jack. Unbolt safety screws (6) and

consequently the nut (5). Take out the spring (4) and crank arm (7). Take out from the hub

(1) the ratchet (3) with brake insert (2A), take off the brake insert (2B), and replace both

brake inserts (2A) (2B).

Fig. 6

Fig. 7

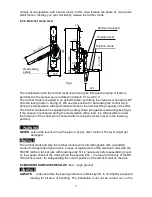

11.2.2 Brake assembly and adjusting (figures 6 and 7)

Proceed in the opposite way when assembling. Slip over the hub (1) the friction insert

(2B); ratchet (3) and second friction insert (2A). Set it in the crank arm (7), slide on the

spring (4) and screw on the nut (5). Tighten the nut so that the clearance in the dent is

from 4 to 6 mm (see fig. 5) and screw down the screws (6).

11.3 GENERAL INSTRUCTIONS

Following instructions give general important information on disassembly, check up, repair

and assembly. If the jack was dismounted from any reason act upon the instructions as

follows.

1. Perform maintenance in clean environment.

2.

NEVER

disassemble the jack more than it is necessary to carrying out the needful

repair.

3.

NEVER

use excessive power when dismantling parts.

4.

NEVER

use heat (fire) as the mean when dismantling parts, if the parts are destined for

next use.

5. Keep the workplace clean and without foreign materials that could get into bearings

and other movable parts.

7

6

5

4

2A

3

2B

1

4 till 6 m m