6

4.3 HANDLING

During transportation and handling, observe technical regulations and standards in force

for work with heavy loads.

5 MAIN SPECIFICATIONS

Load

capacity

(t)

Type

Q

Q

1

Actuating

force on

crank

(N)

Range of

Operating

temperature

Weight

(kg)

15-00

15-00-RK

15-00-VK

15-00-VK-RK

2,5 1,75

380

15

15-00

15-00-RK

15-00-VK

15-00-VK-RK

5

3,5

550

22

HZ

5

3,5 550

1)

330

2)

23

15-01

15-01-RK

15-01-VK

15-01-VK-RK

10

7

540

38

15-01

16

11,2

730

65

Z 23

20

14

800

-20°C

till

+50°C

90

1) Handle in position “crank”

2) Handle in position “lever”

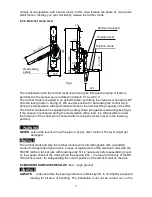

5.1 MECHANICAL DEVICE

Safety and working life of the jack is guaranteed if it works in accordance with specified

classification.

The jack is designed for class 1Bm according to the FEM 9.511 regulation – see table 5.1.

(it corresponds to mechanism classification M3 according to the ISO 4301/1).

Average daily operating time is specified in the load diagram.

Tab. 5.1 MECHANICAL CLASSIFICATION

Load diagram

(load distribution)

Definition

Load coefficient

Average daily

operating time (h)

1

(light)

Jacks usually being subject

to the low load and only in

special cases to the

maximum load.

k

≤

0,50

1 - 2

2

(mean)

Jacks usually being subject

to the low load, but quite

often to the maximum load.

0,50< k

≤

0,63

0,5 - 1

3

(heavy)

Jacks usually being subject

to the mean load, but

frequently to the maximum

load.

0,63< k

≤

0,80

0,25 – 0,5

4

(very heavy)

Jacks usually being subject

to the maximum load or load

approximating to the

maximum.

0,80< k

≤

1,00

0,12 – 0,25

70%

Q1

100%

Q

Fig. 1