11

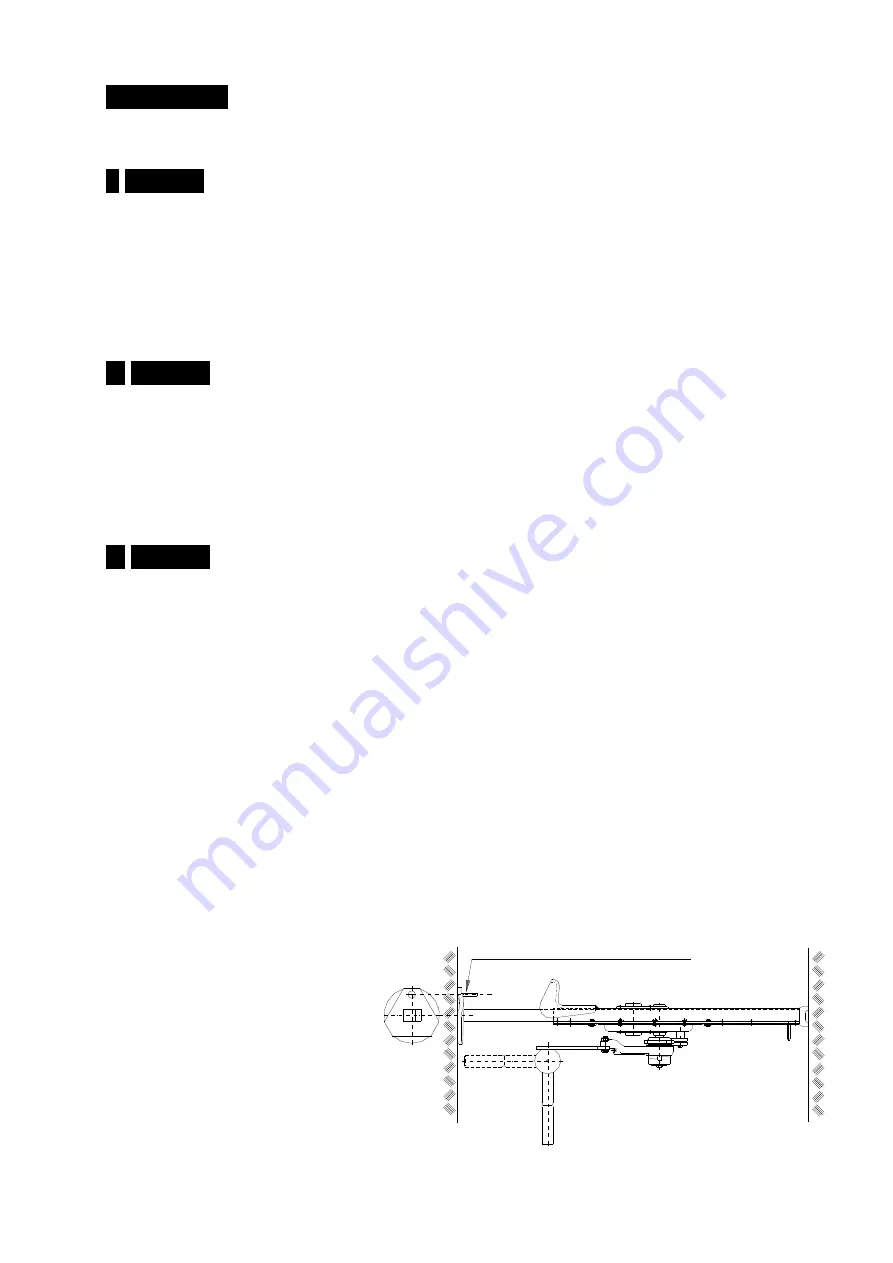

POUŽITÍ VE VODOROVNÉ POLOZE

Fixace pomocí otvoru v patce

Abb. 5

Application in horizontal position

Fastening by the help of the opening in foot

! WARNING

NEVER

extend the lever’s arm with a pipe or by any other method. The lever might

get damaged

! NOTICE

The ratchet crank and also the ratchet crank-lever is interchangeable with a standard

crank of correspondent type of jack. In case of replacement of the standard crank

with the RK 300 ratchet crank at jack with load capacity 5t it is necessary before

assembling to put on the square shank of the crank pinion the spacing tube – it is a

part of delivery of the RK 300 ratchet crank– for safeguarding the correct position of

the ratchet crank on the jack.

6.4 BEARING SURFACE CHECK-UP /floor, rough ground/

! NOTICE

ALWAYS

make sure that the bearing surface is sufficiently firm to hold tightly

supposed loading for all time of handling. The installation must not be

carried out on the surface where it is not possible to determine the load-

bearing capacity or that is instable.

ALWAYS

the operation personnel are responsible for the set-up!

6.5 TEST PRIOR TO USE

! NOTICE

(1) At first read again the previous articles of this manual and make sure that all steps

were correctly done and all parts are safety mounted.

(2) Visually check the jack and bearing surface whether they are without defects.

(3) Put to proof the jack function by the motion of the crank without loading.

(4) Carry out several jacking up and lowering with the suitable load (10% till 50% of the

load capacity). At the same time verify, whether the jack will hold firmly the load

without slipping when lowering and stopping.

7 OPERATION

7.1 APPLICATION OF THE JACK

7.1.1 The jack is multifunctional equipment destined for manual jacking up, lowering,

pushing and spreading of subjects in the workplace determined by the user. It

can be used not only in a current environment, but also in environments with

explosion risk in the event that there

is the symbol of the

protection type marked on

the label – see articles

2.3, 2.4 and 5.3 of this

OM. The lifters type

15-00

(load capacity 2,5 and 5t)

have an opening in the

foot which simplifies work

when

pushing

apart

objects

above

head

height. The lifter’s foot can

be easily attached in the

required position by using

a screw for example, without the need to use a helper. (fig. 6)

Fig. 6