5

-

OPERATION & WORk

5

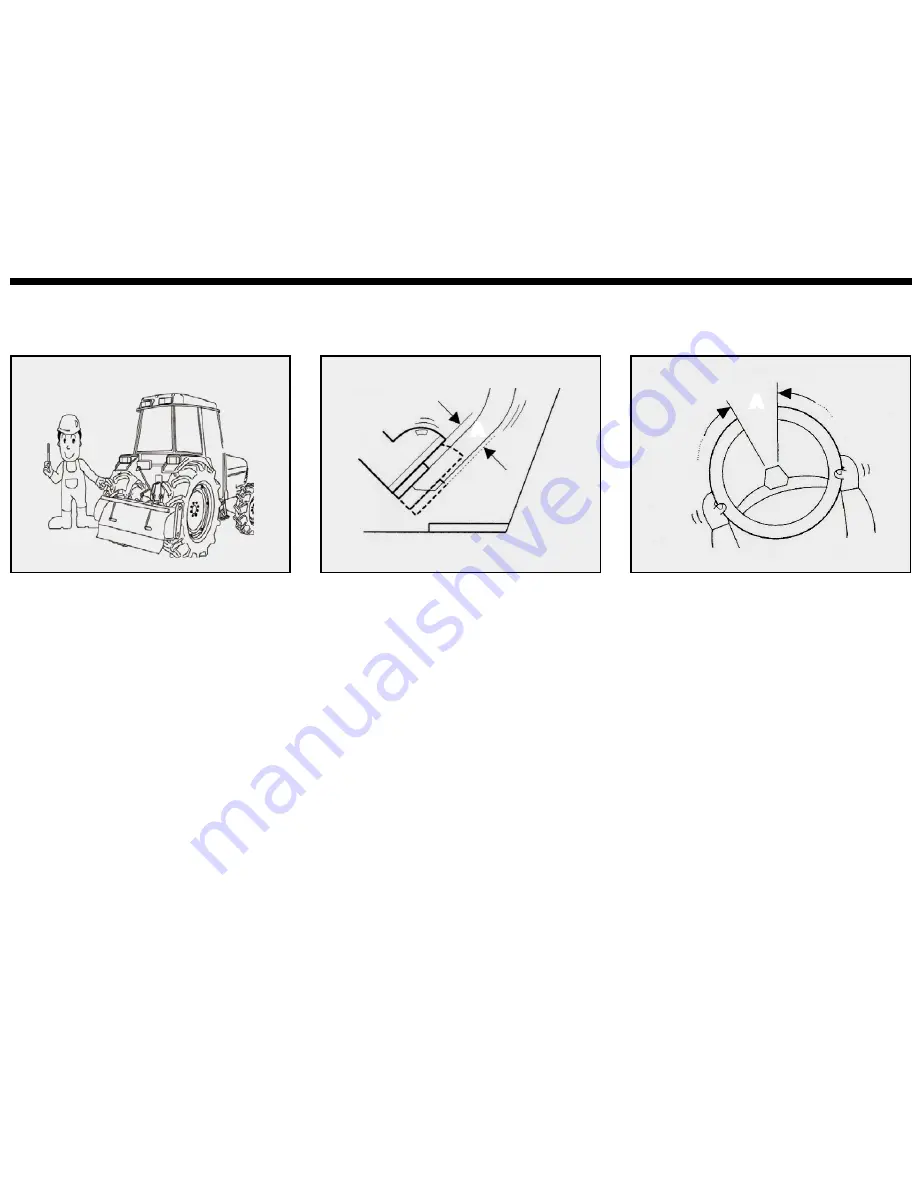

bR25O509A

4. Check around the implement.

• Condition of the locking pin of

the universal joint inserted in the

PTO shaft.

• Condition of R pins in each part.

• Loosening of the bolts holding

the blade.

• Quantity of oil in each part. for

more details, please refer to the

implement manufacturer’s in-

structions.

bR25O510A

bR25O511A

5. Check on the driver seat.

• Operational condition and free

play of the brake. (0.2~0.4 in)

• free play of the steering wheel.

(0.8~2.0 in)

A

(A) free play 0.2 ~ 0.4 in

(A) free play 0.8 ~ 2.0 in

A

Summary of Contents for 9550C

Page 2: ...BRANSON 9550C 00 indd 2 2015 12 22 8 53...

Page 47: ...2 2 ABOUT WARRANTY WARRANTY 2 2 TROUBLE SHOOTING 2 2 BRANSON 9550C 02 indd 1 2015 12 15 3 31...

Page 49: ...3 3 OVERVIEW OF THE TRACTOR EXTERIOR VIEW 3 2 BRANSON 9550C 03 indd 1 2015 12 22 8 54...

Page 52: ...MEMO Branson Machinery LLC BRANSON 9550C 03 indd 4 2015 12 22 8 54...

Page 154: ...MEMO Branson Machinery LLC BRANSON 9550C 07 indd 24 2015 12 16 2 32...

Page 166: ...MEMO Branson Machinery LLC BRANSON 9550C 09 indd 6 2015 12 16 8 47...

Page 167: ...10 INDEX 10 2 10 INDEX BRANSON 9550C 10 indd 1 2015 12 16 2 12...