5 Introduction

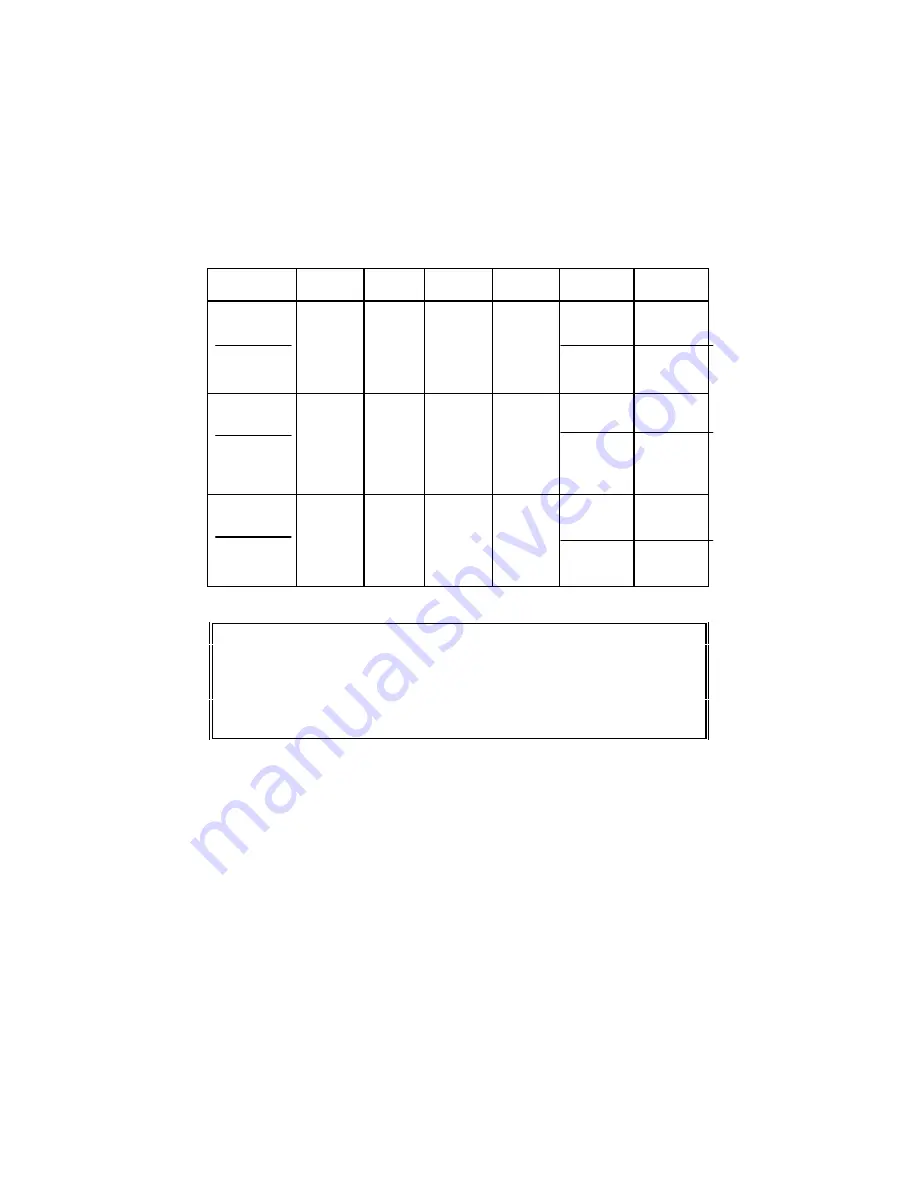

Equipment Specifications

Model

Tank

Volume

Tank

Size

Overall

Size

Weight

Heater

Power

Input

Power

PC620R-1

PC620R-2

2.75 gal.

(8.5 L)

L: 19.5”

W: 5.8”

D: 6”

L: 20.3”

W: 6.3”

H: 10.5”

23 lbs.

(10.5Kg)

None

180 Watts

115 V

1.4A

115 V

3.1A

PC-620E-1

PC620E-2

2.75 gal.

(8.5 L)

L: 19.5”

W: 5.8”

D: 6”

L: 20.3”

W: 6.3”

H: 10.5”

24 lbs.

10.9 Kg)

None

180 Watts

230 V

.7A

230 V

1.6A

PC-620J-1

PC-620J-2

2.75 gal.

(8.5 L)

L: 19.5”

W: 5.8”

D: 6”

L: 20.3”

W: 6.3”

H: 10.5”

24 lbs.

10.9 Kg)

None

135 Watts

100 V

1.6A

100 V

3.1A

NOTE:

•

All models have a frequency of 44 kHz.

•

Cleaners have NRTL/CSA approval and comply with FCC regulations.

•

All 230V units meet CE standards.

•

Units may cause GFI outlets to trip.

•

All units have a ground leakage current less than .50ma.

Summary of Contents for PC-620-1

Page 1: ...Operator s Manual PC 620 1 PC 620 2 Tabletop Ultrasonic Cleaners...

Page 4: ......

Page 20: ...CPN 214 159...