Chapter 2: Introduction to the SLPt Cell Disruptor

Controls and Commands

2-2

100-214-252 Rev. A

The digital controls on the SLPt Cell disruptor allow for accuracy and repeatability of control settings.

Application parameters are entered into the power supply through the keypad on the front panel of the unit.

External signals are initiated via J2 (9 pin) connector on the back of the power supply. To simply generate

a start signal, a J911 Start cable, 8’, (EDP101-240-020) can be used. To control or monitor other signals

(Reset, Seek, Alarm, Ready) a J913 Start cable, 25’, (EDP101-240-072) must be used. Reset and Start func-

tions can also be performed from the front panel. Further information about these signals can be found in

Section 4.6.2. All other functions can only be performed from the front panel.

The SLPt Cell Disruptor’s power supply converts AC line voltage to 40kHz electrical energy. This high-

frequency electrical energy is fed to a converter where it is converted to mechanical vibrations. The heart of

the converter is a lead zirconate titanate electrostrictive element which, when subjected to an alternating

voltage, expands and contracts. The converter vibrates in a longitudinal direction and transmits this motion

to the tool immersed in the solution, which causes cavitation. The implosion of microscopic cavities in the

solution results, causing the molecules in the medium to become intensely agitated. The ultrasonic vibra-

tions transmitted through the tool can also be applied directly to a solid workpiece, such as tissue, through

the tool that are attached to the converter.

The SLPt Cell Disruptor is a constant amplitude device. As the load or pressure on the tool face increases,

the power supply develops more power to maintain the amplitude for any given output control setting. When

the tool is operated in air, it is subjected to minimum pressure, and minimum power is required to maintain

amplitude.

The load increases when the tool is immersed in a liquid; the more viscous the liquid, the higher the load

and the more power developed. If a cell that can be pressurized is used, even more power is developed. For

any given application, more power results when a tool of higher amplitude or larger radiating surface is

used, or when any tool is driven at higher amplitude by increasing the amplitude.

By setting various operation parameters, you can precisely control the way in which ultrasonics are applied

to the sample. You can:

•

Specify the time duration of the experiment

•

Adjust the amplitude setting between 10% and 60% of maximum amplitude (microtip 60% max-

imum)

•

Prevent excessive temperature increase in the sample by setting ultrasonics to operate in Pulse

mode or in Pulse/Pause mode

•

Bring a sample to a desired temperature and hold it there, varying by only a few degrees, for a

desired duration using the Pulse/Pause mode

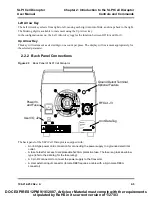

2.2 Controls and Commands

This section describes the controls and commands that you use to operate the SLPt Cell disruptor. A detailed

description of how and when to use each front panel control, the valid formats for the data that you enter,

and the response you receive from the system when you use each of these controls is provided in

Chapter

6, Operations

.

The SLPt Cell disruptor is equipped with a keypad and LED display on the front panel of the unit. With the

keypad, you can set functional modes of operation and input digital parameters. Availability of the various

functions depends on the mode or state of the system. If you attempt to use a function that is not available,

you will be alerted by a beep.

DOC EXPIRES 12PM 9/16/2007. Article or Material must comply with the requirements

stipulated by RoHS in its current version of 1/27/03