Chapter 4: Installation and Setup

Ultrasonic Test

4-10

100-214-252 Rev. A

4.8 Ultrasonic Test

The Test button on the front panel of the SLPt Cell Disruptor is used to verify that the unit is functioning

(providing ultrasonic energy to the Converter and Horn). Later, you can run another test on the system for

your particular experiment (described in

5.3 System Performance Benchmark

).

Before testing the SLPt, always make sure that the horn is not touching anything. The System also performs

several self-tests when it is first turned on.

Use the following charts to determine the correct system settings for

the tools you are using.

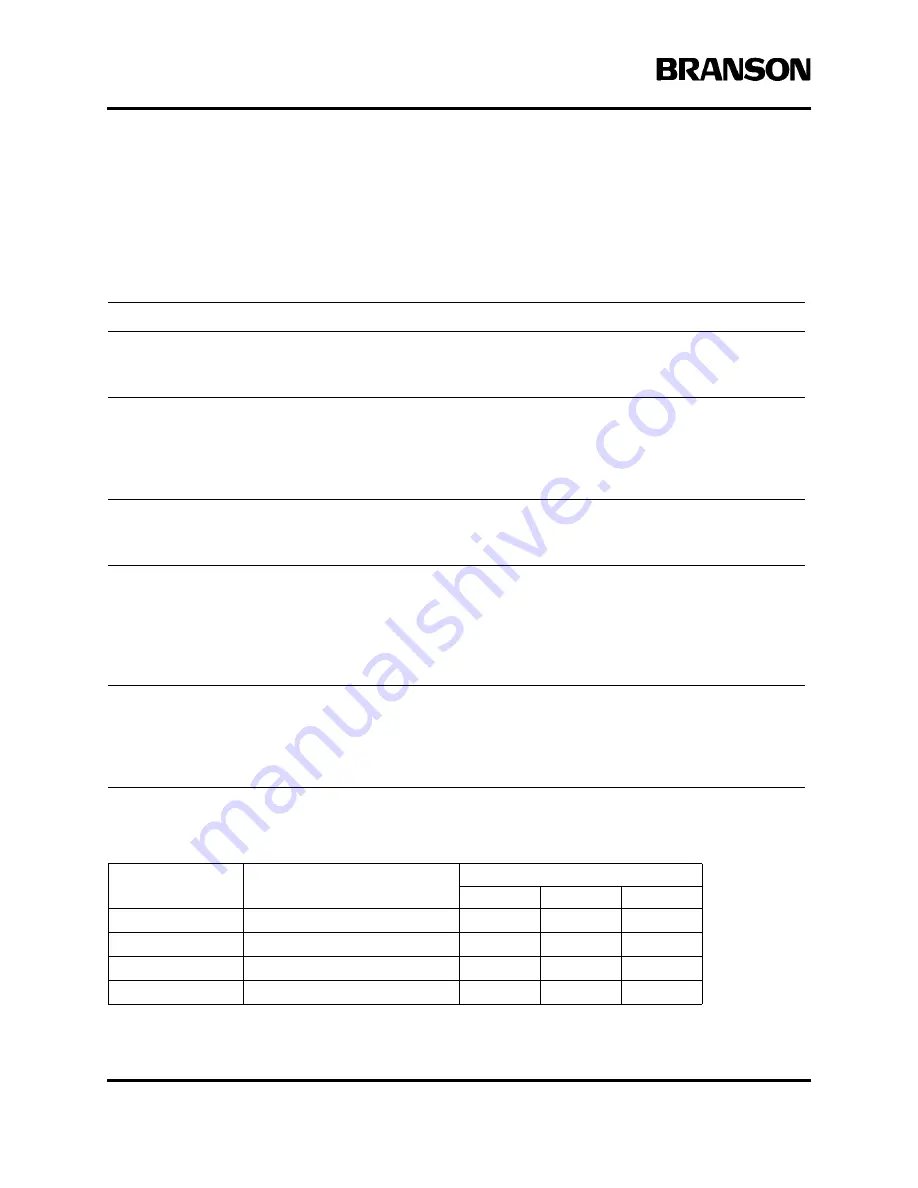

Table 4.3

Approximate Microtip Amplitudes in Microns

Step

Do this...

To obtain this result

1

Set up the SLPt Cell Disruptor follow-

ing the instructions in this manual.

Connect the microtip to the converter.

Prepare the Sonifier to operate, if it was not previ-

ously assembled.

2

Connect the RF cable to the power

supply. Turn the Unit On, and observe

the self-test displays.

Verify that the system passes all its self-tests,

observing that there are no error messages on the

front panel display.

The SLPt Cell Disruptor advances to the “Ready”

mode and shows the normal Ready display .

3

Adjust the Amplitude control to

approximately 50% (observe the

value on the front panel display).

Ensures that ultrasonic energy will be at some mid-

range value, and will not cause damage. Refer to

Table 4.3 for amplitude information.

4

Verify that the Horn is not touching

anything.

Press and hold the Test button

on

the front panel. The test will run until

the test key is released. Observe the

front panel display.

Verifies the ultrasonic output of the system. You may

hear a soft, high-pitched sound.

5

If the system showed readings on

the display during the Test,

you may either proceed with your

experiments, or

Turn the unit off.

Verification that the SLPt Cell Disruptor is operating

and is ready to be set up for your experiment.

Microtip EDP No.

Description

Amplitude Control Settings

10%

40%

70%

109-122-1064

0.250” Diameter Tapered

5

15

30

109-122-1182

0.190” Diameter Tapered

12

38

74

109-122-1065

0.125” Diameter Tapered

12

34

68

109-122-1066

0.091” Diameter Tapered

14

32

64

* All measurements in microns unless otherwise specified

DOC EXPIRES 12PM 9/16/2007. Article or Material must comply with the requirements

stipulated by RoHS in its current version of 1/27/03