Page 11

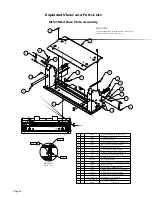

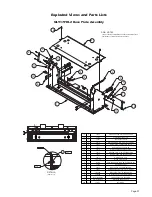

Inner/outer fold arms (2)

Platform pivot pin bearings (4)

Outer fold arm bearings (8)

Inner roll stop pivot bearings (2)

Inner roll stop lever bearings (2)

Inner roll stop lever slot (2)

Saddle support bearings (8)

Inner fold arm roller pin bearings (4)

Inner fold arm cam followers (4)

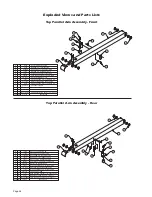

Parallel arm pivot pin bearings (16)

Handrail pivot pin bearings (4)

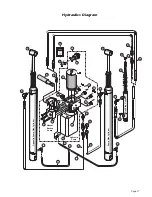

Hydraulic cylinder pivot bushings (8)

Outer barrier lever guide slot

Inspect Lift-Tite

™

latch rollers for wear or damage,

positive securement and proper operation (2)

Inspect inner roll stop for:

• Wear or damage

• Proper operation. Roll stop should just rest on top

surface of the threshold plate.

• Positive securement (both ends)

Inspect handrail components for wear or damage,

and for proper operation

Inspect microswitches for securement and proper

adjustment.

Make sure lift operates smoothly

Inspect external snap rings:

• Outer fold arm (6)

• Lift-Tite

™

latch roller (2)

• Lift-Tite

™

latch gas (dampening) spring (4)

• Inner fold arm cam followers (4)

• Inner fold arm roller pins (4)

• Outer barrier hydraulic cylinder mounting pin (2)

• Inner roll stop lever bracket pins (2)

Inspect inner roll stop locks (2) and torsion springs

(2) for wear or damage and for proper operation.

Inspect lift for rattles

Correct as needed.

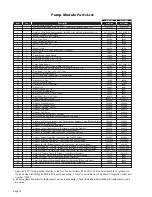

Perform all procedures listed in previous section also

750

Cycles

1500

Cycles

Maintenance and Lubrication Schedule

continued

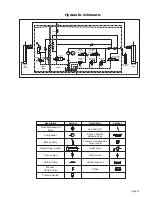

Apply grease (synthetic) to contact areas between

inner/outer fold arms. See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Grease to both sides of slot.

See Lubrication Diagram

Correct, replace damaged parts and/or relubricate.

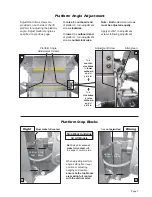

Resecure, replace or correct as needed. See

Platform Angle Instructions and Tower Microswitch

Adjustment Instructions.

Replace damaged parts.

Resecure, replace or adjust as needed. See

Microswitch Adjustment Instructions.

Realign towers and vertical arms. Lubricate or

correct as needed.

Resecure or replace if needed.

Replace damaged parts. Apply Light Oil to inner

roll stop lock pivot point.