Page 3

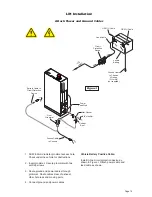

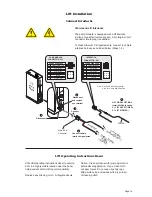

Route all cables clear of exhaust system, other hot areas, moving parts, wet areas, etc.

5LVNRIHOHFWULFDOVKRFNRUÀUH8VHH[WUDFDUHZKHQPDNLQJHOHFWULFDOFRQQHFWLRQV

Connect and secure as outlined in Installation Instructions and Wiring Diagrams.

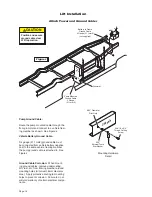

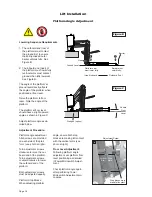

$GMXVWSODWIRUPDQJOHDQGÁRRUOHYHOSRVLWLRQLQJRIEULGJHSODWHEHIRUHRSHUDWLQJOLIWZLWK

passenger.

Maintenance and repairs must be performed only by authorized service personnel.

Perform maintenance and lubrication procedures exactly as outlined in the

Maintenance and Lubrication Schedule contained in this manual.

Disconnect the power cable at the battery prior to servicing.

Never modify (alter) a Braun Corporation lift.

Replacement parts must be Braun authorized replacements.

Never install screws or fasteners (other than factory equipped).

Whenever replacing a hydraulic cylinder or seals, lower platform fully.

Failure to follow these safety precautions may result in serious bodily injury and/or

property damage.

WA

RNING

WA

RNING

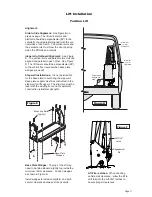

Read this manual, supplement(s) and lift-posted operating

instructions decals before performing installation,

operation, or service procedures.

Use appropriate personal protective equipment when

installing and servicing lift.

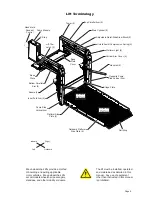

Remove any obstructions within the lift mounting/

operating area prior to beginning installation procedures.

Install lift and power platform to fully folded position before

removing shipping straps.

Do not fold or unfold the platform prior to positive

securement of base plate mounting hardware.

Check for obstructions such as gas lines, wires,

exhaust, etc. before drilling or cutting during installation

procedures.

WA

RNING

WA

RNING

WA

RNING

If installation, main-

tenance or repair

procedures cannot

be completed ex-

actly as provided in

this manual or if the

instructions are not

fully understood,

contact The Braun

Corporation immedi-

ately. Failure to do

so may result in seri-

ous bodily injury and/

or property damage.

Service Safety Precautions

Installation and Service Safety Precautions

WA

RNING

WA

RNING

WA

RNING

WA

RNING

WA

RNING

WA

RNING

WA

RNING

WA

RNING

WA

RNING

WA

RNING

WA

RNING

WA

RNING

WA

RNING

Summary of Contents for Century 2 CLXT

Page 42: ...Page 40...