Page 7

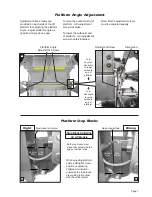

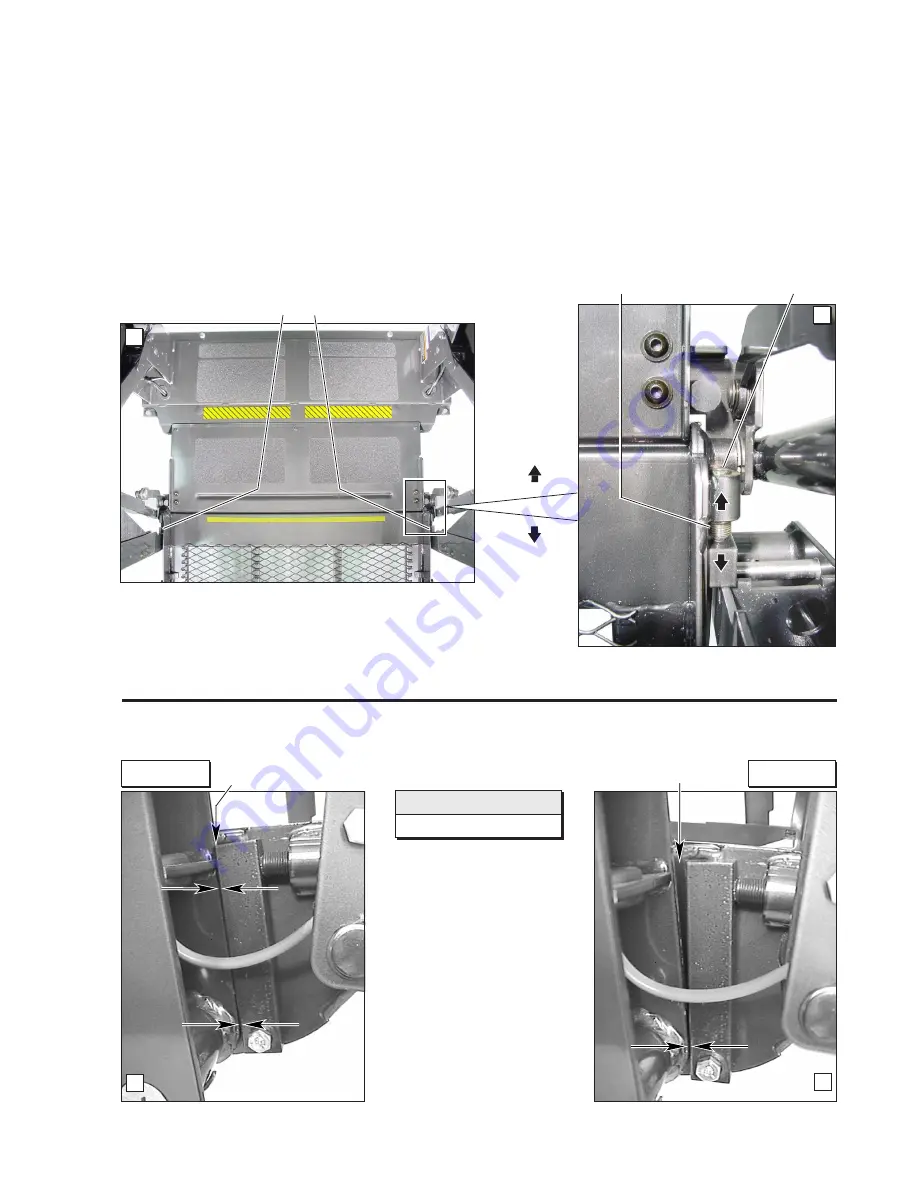

Platform Angle

Adjustment Screws

Adjustment Screw

Allen Head

B

C

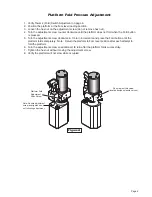

Platform Angle Adjustment

Adjustment Allen screws are

provided on each side of the lift

platform for adjusting the platform

angle. Adjust platform angle as

specified on previous page.

Platform Stop Blocks

Must make full contact.

Gap not permitted.

Both stop blocks must

make full contact with the

edge of vertical arms.

D

E

Stop Block Guideline

All Lift Models

Right

Wrong

Turn

clockwise

to raise

outboard

end of

platform

When adjusting platform

angle, setting floor level

position or adjusting

bridging microswitch -

ensure both stop blocks

are making full contact

with the vertical arms.

Stop

Block

Vertical

Arm

Stop

Block

Vertical

Arm

Turn

counter-

clockwise

to lower

outboard

end of

platform

To raise the outboard end of

platform - turn adjustment

screw clockwise.

To lower the outboard end

of platform - turn adjustment

screw counterclockwise.

Note: Both adjustment screws

must be adjusted equally.