16

Occupant restraints

1.

Bolted occupant restraints will have been installed in the vehicle in accordance with our

own and the vehicle converter’s instruction.

Note:

if fitting hardware, other than that

provided in this kit, is to be used, then the fixing bolts should be of an equivalent cross

section and an equivalent grade, namely B.S. Grade ’S’ (ISO 8.8).

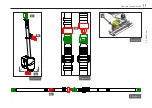

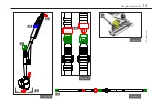

2. The componentry is assembled with the upper 3rd point and lower reel anchorage points

bolted to an approved anchorage position on the vehicle body. The inertia reel should

be mounted at an angle of 90/90° as viewed in 2 planes to the road level, (Fig 7A). The

reel and its bracketry is bolted through the vehicle and reinforced on the underside, if

required, with the 100mm diameter load spreader plate and nyloc nut. All bolts should

be tightened to a torque of 40Nm.

Note: All vehicle anchorage points may require

reinforcement as necessary to meet any required minimum strength recommendations

for the vehicle.

3. Once installed, check the free running ofthe webbing into, and out of, the inertia reel and

check the ’lock up’ facility of the reel by engaginga short tug at various intervals along

the extension and retraction of the webbing in and out of the reel.

4. Draw the shoulder belt buckle, (Fig. 7B), across the upper body and attach to the lap belt

tongue, (Fig. 3A & 4A), to complete the 3 point belt system.

5. Note: The lap belt (pelvic) restraint is designed to bear upon the bony structure of the

body and should be worn low across the front of the pelvis with any junctions between

the pelvic and shoulder restraints located near the wearer’s hips.

6. Adjust the tensioner, (Fig. 7C) so that it sits just above the occupant’s shoulder.

Removing the TOR

Shoulder Belt

1.

Unfasten the buckle

from the occupant’s

hips, remove the

shoulder belt restraint

and let the webbing

retract back into the

housing.

Fit and use

TOR Adjustable Shoulder Belt occupant restraint

Bolted