48- 55

62- 76

A

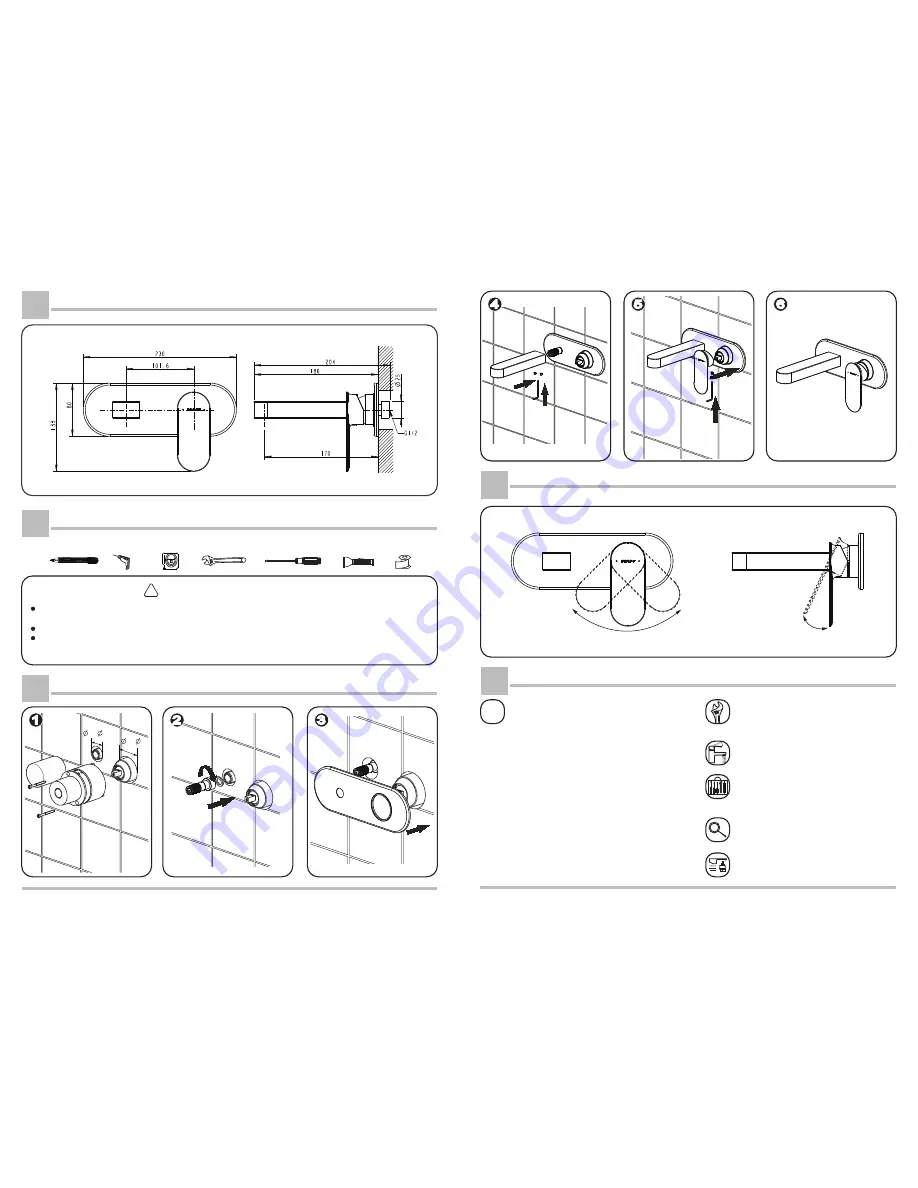

INSTALLATION DIMENSION

Unit:mm

2

Designed and developed by Bravat/Dietsche Germany

B

HELPFUL TOOLS

Before installing the new mixer, it is essential that you thoroughly flush through the supply pipes in order to remove any remaining swarf,

solder or other impurities. Failure to carry out this simple procedure could cause problems or damage to the workings of the mixer.

Work water pressure

:

0.15 - 1.0 MPa (Including cold and hot).

If the pictures and statements in the ‘Installation Specifications’ is unconfirmed with practicality, please take practicality as standard.

!

Points for attention before installation

INSTALLATION STEP

C

3

Designed and developed by Bravat/Dietsche Germany

FAUCET OPERATION

D

Spanner

Teflon tape

Screwdriver

Flashlight

Tape Measure

Impact Drill

Pencil

SPECIFICATION

E

Application:

Operation with unpressurized storage heaters is not possible.

Use for indoor public places and common residence.

Specifications:

Hot and cold water inlet pressures should be equal.

Static inlet pressure range: 0.15 - 1.0 MPa

New regulation: 0.5 MPa maximum static pressure at any outlet

within a building.

(Installation shall be in accordance with the AS/NZS3500 series

of Standards.)

Hot water inlet temperature: max. 80

℃

Recommended (energy saving): 60

℃

Environment temperature: 5

℃~

45

℃

If static pressure exceeds 5 bar, a pressure-reducing valve must

be fitted.

Avoid major pressure differences between hot and cold water supply.

This technical product information is exclusively

for the installer or trained specialists.

Please pass these instructions on to the user.

GB

Installation:

Flush piping system prior and after installation of

fitting thoroughly (Consider EN 806)!

Fitting a temperature limiter is possible.

Function:

Check connections for leaks and check function of

fitting.

Maintenance:

Inspect and clean all components and replace if

necessary.

Shut off water supply for maintenance work.

When installing the cartridge, ensure that the seals

are correctly seated.

Tighten the screws evenly and alternately.

Replacement parts: see exploded drawing

.

Care: see Care Instructions.

4

5

6

1

2

3

25°

Close

Open

Hot

Cold

90°

Finished