200 SERIES TWO-MAN AUGERS

FORM GOM08042004US, VERSION 1.1

English-EN

15

36. Disconnect spark plug wire to prevent accidental engine starting.

37. When engine is not in operation or is to be stored, close fuel tank

breather vent (if so equipped). Turn fuel tank ON/OFF valve to OFF

position to minimize fuel flooding carburetor and/or entering engine

crankcase and/or impacting upon environment.

11 MAINTENANCE INSTRUCTIONS

For routine maintenance, the following information should be followed once per

week or 40 hours of use at minimum for maximum performance and return on

investment unless otherwise indicated. Information is for reference only and is

not intended to be all inclusive.

1.

Use factory approved replacement parts/accessories only for

maintenance and repair.

2.

All maintenance/repairs not described in this operator manual must be

done by a dedicated service center following a specific service/repair

manual.

3.

STOP Auger BEFORE performing maintenance and service per

STOPPING AUGER in OPERATING INSTRUCTIONS section of this

manual.

4.

Inspect for loose or broken parts. Inspect all fasteners, individual parts,

operator controls and safety devices for proper function. Tighten

fasteners as necessary. Replace any worn or damaged part or assembly.

5.

Remove all loose accumulations, dirt, grease to prevent safety hazards,

poor performance and reduced service life using safety type solvent.

6.

Inspect engine throttle control arm and throttle cable assemblies are not

damaged, bent, abraided or parts missing, are in correct operating

position and allow for complete freedom of movement. DO NOT operate

Auger with damaged engine throttle control arm and/or throttle cable

assembly.

7.

Inspect operator grips and throttle control grip are free of moisture, pitch,

oil or grease and are not cracked, damaged or worn. DO NOT operate

Auger until such handles and/or grips are repaired and/or replaced to

prevent aggravated effects of “kickback and/or loss of operator control

when digging.

8.

Inspect operator handle full length and attach areas for signs of cracking,

fatigue, deformation, nicks or gouges. If cracking or deformation is

detected or cuts or abrasions greater than 0.125 inch (3.2 mm) deep are

present, replace. Keep handles clean and free of dirt, moisture, grease,

oil and other, foreign material accumulations.

IMPORTANT:

Keep

external condition of operator handles, grips and throttle

control free of accumulation of moisture, dirt, pitch and other foreign substance

that can provide a conductive pathway for energy to be transmitted. Throttle

control should be maintained in clean, dry condition and free of all foreign

materials.

IMPORTANT:

Regardless of actual use, operator handles have a maximum

service life of 6 years. Replace any operator handles meeting this time limit.

Handle material used reduces (but does not eliminate) long term effects of ultra

violet radiation from sun.

9.

Inspect centrifugal clutch assembly properly disengages at specified

engine speed or slips during overload conditions.

10. Inspect engine muffler for wear or damage and replace as necessary to

minimize fire hazard and hearing loss risk. If muffler is equipped with a

spark arresting device, check for proper working condition. If not, replace

with approved replacement from engine manufacturer.

IMPORTANT:

It is owner(s) and/or operator(s) responsibility to provide and

maintain a USDA approved, spark arresting muffler in an operating area

specified by law. Check appropriate governing agencies for more specific

information. Auger must not be operated if muffler is faulty or has been

removed.

11. Inspect all safety and operation decals. If any decal becomes damaged

and/or unreadable, replace.

12. Auger may utilize self-locking type hexagon nuts to minimize effects of

vibration. If worn or damaged, replace.

13. Inspect auger bit for bent or damaged axle that will cause auger bit to

“wobble” during use and can cause loss of machine control. Maximum

allowable auger bit wobble is 0.25 inch (7 mm) total indicator runout

(TIR). Auger bits with TIR in excess of this value must be removed from

service and scrapped.

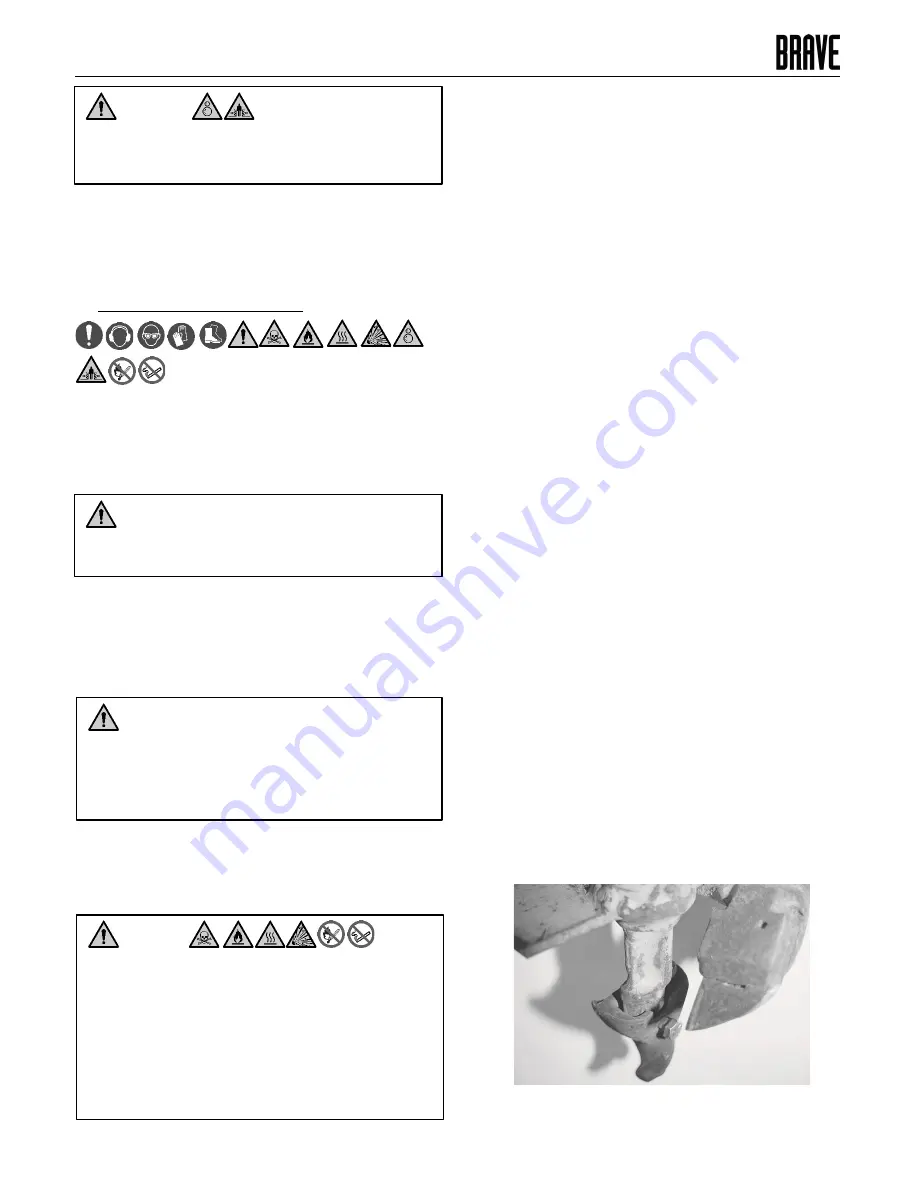

14. Inspect auger bit teeth and screw bit for excessive wear, cracking,

sharpness and missing parts. Replace as required to prevent undo wear

to boring head and inverted cone configuration to auger flighting. The end

result is substandard productivity and usually requires complete auger bit

replacement. FIGURE 21. Auger bit service life can be greatly extended

with constant auger bit wear part maintenance.

FIGURE 21

WARNING

•

Operating Auger utilizing components not meeting

minimum operational standards can result in property

damage and/or personal injury.

WARNING

•

Stop Auger between each hole.

•

Never leave Auger running and unattended.

•

Not doing so can result in property damage and/or

personal injury.

WARNING

•

DO NOT perform service and/or repair related functions

with Auger mounted to 999 Series Display Stands.

•

Stands are not designed and/or intended for hole digging

and service functions.

•

Such use can result in property damage and/or personal

injury.

DANGER

•

Use safety type solvent.

•

DO NOT use thinner, benzene, or other volatile solvents

that will attack rubber/plastic components when cleaning

Auger.

•

Provide adequate ventilation.

•

DO NOT smoke while using cleaning solvents.

•

DO NOT use solvents with engine running or if it is hot.

•

Allow ample time for engine to cool BEFORE using

solvents.

•

An ignition source in close proximity to hot engine can be

the source of an explosion, resulting in property damage

and/or personal injury.