200 SERIES TWO-MAN AUGERS

FORM GOM08042004US, VERSION 1.1

English-EN

17

FIGURE 24

6.

Apply appropriate preservative to rubber boot assembly to protect internal

components from foreign material accumulations.

7.

If regular throttle control inspection determines carburetor return spring

does not properly return to engine cut-off position, remove throttle control

grip tube from throttle control handle. Inspect tube and operator handle

surface area for accumulation of foreign material, including dirt, moisture,

etc. Remove any accumulation, clean as necessary. DO NOT apply

external lubrication to this area during reassembly process.

8.

Inspect throttle control grip proper attachment to throttle control

assembly. Replace grip which fits loose or has become worn/damaged.

REPLACING WORN AUGER SCREW BIT

Application: All 1-3/8 inch hexagon and 7/8 inch square drive series auger bits.

Tools Required:

1 each, safety glasses

1 each, hammer

2 each, 1/2 inch (14 mm) wrenches

Parts Required:

1 each, PN BR10619 Screw Bit for 14 inch (355.6 mm) to 18 inch (457.2 mm)

diameter auger bits

1 each, PN BR10621 Screw Bit for 6 inch (152.4 mm) to 12 inch (304.8 mm)

diameter auger bits

1 each, PN BR10625 Screw Bit for 4 inch (101.6 mm) diameter auger bit

NOTE:

Tungsten Carbide versions of each screw bit listed above are available.

These optional hardfaced screw bits will not increase overall productivity rates,

but will increase anticipated service life of the screw bit.

NOTE:

Replacement of auger screw bit will require a level working platform of

appropriate size and height.

1.

Using wrenches, remove cap screw retaining bit screw to the auger bit

drive lug. Remove bit screw and properly dispose of.

2.

Inspect auger bit drive lug for signs of excessive wear and/or damage. To

replace drive lug, remove by using suitable saw or cutting torch.

3.

Install replacement screw bit and retaining hardware. Hardware is

unidirectional. Secure tight with wrenches.

4.

Return auger bit back to service.

REPLACING WORN AUGER BIT TEETH

Application: All 1-3/8 inch hexagon and 7/8 inch square drive auger bits.

Tools Required:

1 each, safety glasses

2 each, 1/4 inch (6.4 mm) diameter drift punch.

1 each, plastic hammer or soft type hammer designed for impact use.

Parts Required:

Required Quantity, PN BR10614 Standard Dirt Tooth or,

Required Quantity, PN BR10615 Hardfaced Dirt Tooth or,

Required Quantity, PN BR10616 Chisel Tooth or,

Required Quantity, PN BR10617 Tungsten Carbide Chisel Tooth or,

Required Quantity, PN BR10618 Tungsten Carbide Tooth

NOTE:

Replacement of auger bit teeth will require level working platform of

appropriate size and height.

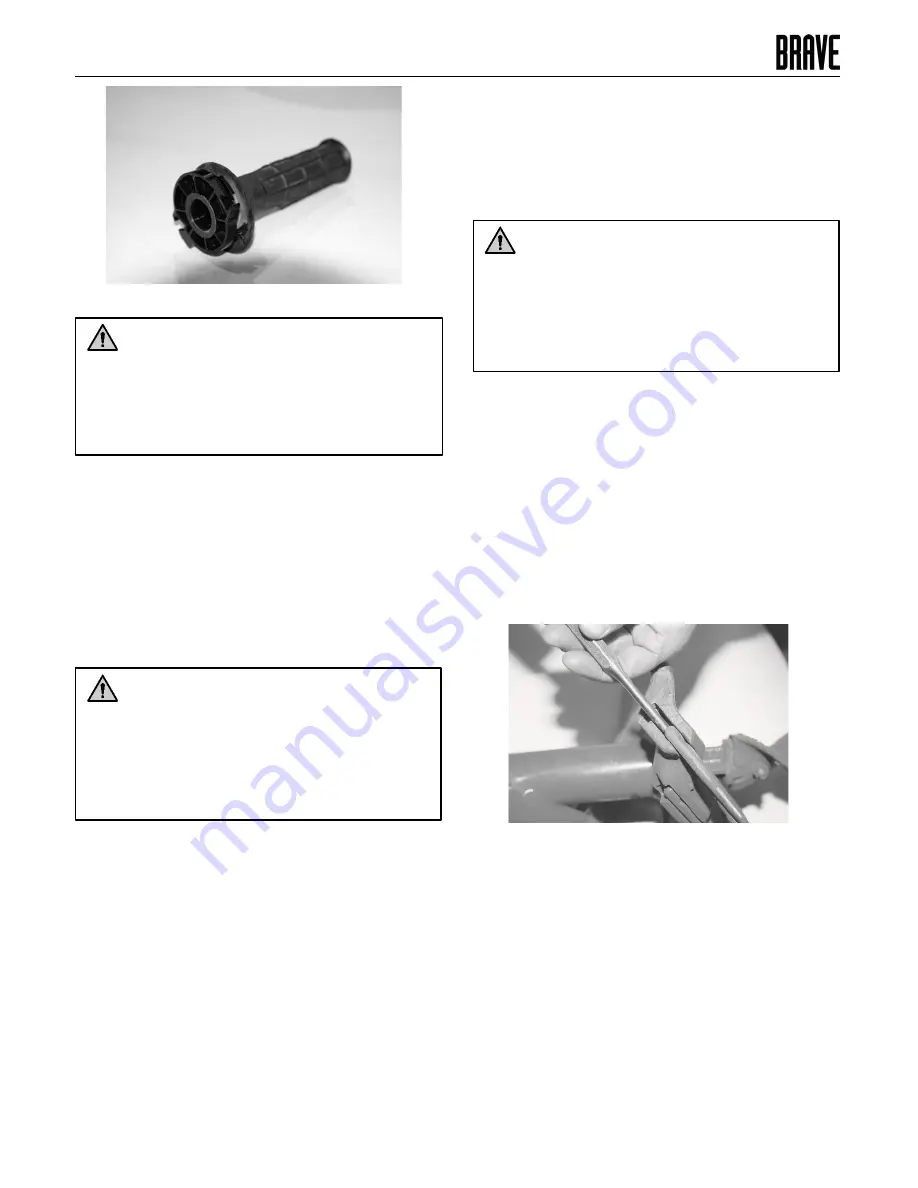

1.

Using hammer and drift punch, strike the visible end of tooth located in

tooth retention slot. Repeat action until worn tooth becomes loose and

can be removed. FIGURE 25

FIGURE 25

2.

Remove worn rubber lock from tooth retention slot. Both round and flat

locking device configurations are utilized.

3.

Inspect tooth retention slot area of casting for excessive wear and/or

damage.

NOTE:

A tooth retention socket with excessive wear will not properly support a

replacement tooth. Excessive wear usually indicates an auger bit is worn

beyond its useful service life and should be removed from service. An auger bit

with excessive wear is depicted in FIGURE 26.

DANGER

•

Wear safety eyewear and other safety apparel appropriate

for the job application and/or job site environment.

•

Screw bit replacement process can create flying steel

chips and/or other debris.

•

Caution all onlookers regarding the possibility of and/or

to remain clear of flying debris.

•

Improper safety procedures can result in property

damage and/or personal injury.

DANGER

•

Wear safety eyewear and other safety apparel appropriate

for the job application and/or job site environment.

•

Screw bit replacement process can create flying steel

chips and/or other debris.

•

Caution all onlookers regarding the possibility of and/or

to remain clear of flying debris.

•

Improper safety procedures can result in property

damage and/or personal injury.

CAUTION

•

DO NOT operate Auger without rubber boot in proper location

or in poor condition.

•

Without boot assembly, foreign material can accumulate

within throttle control assembly.

•

Such an occurrence can restrict movement of internal

components, reducing operator control of Auger and result in

property damage and/or personal injury.