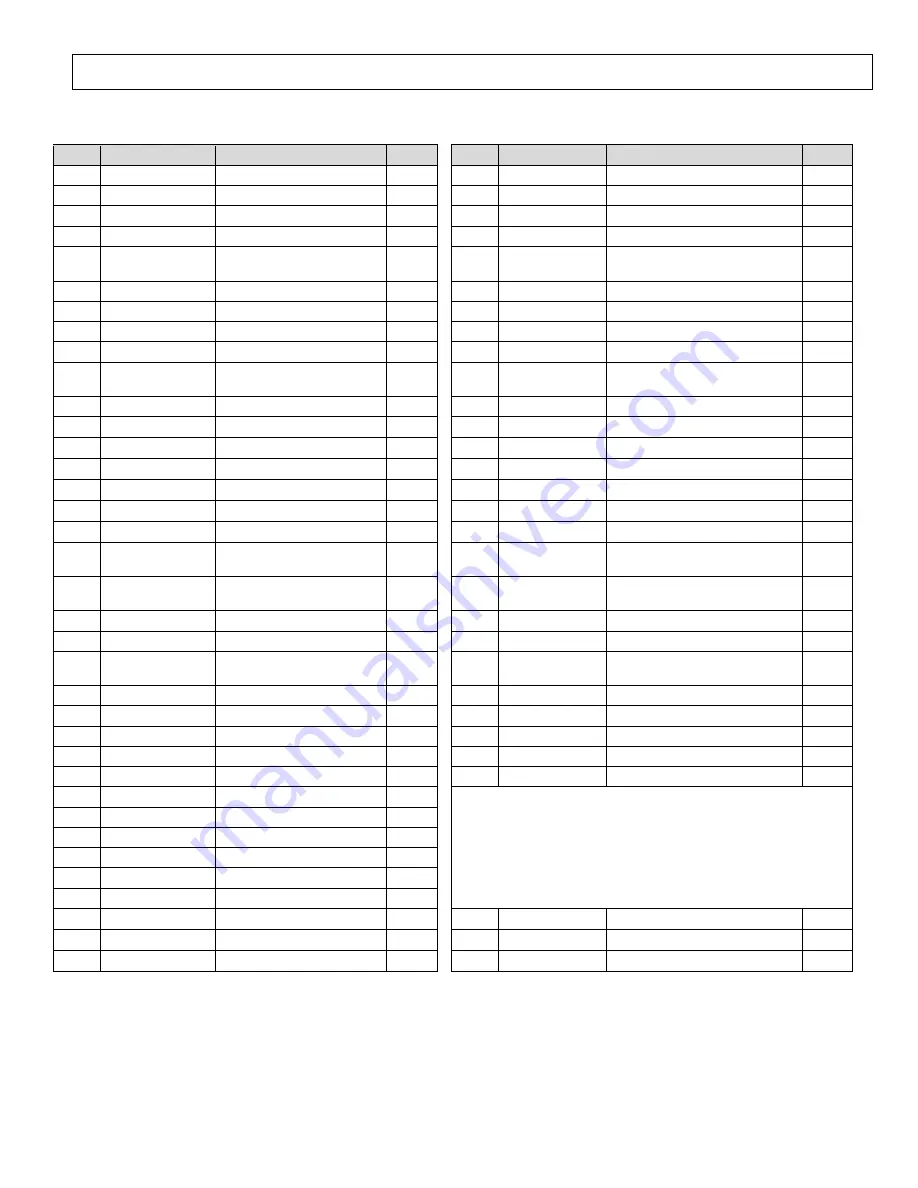

Pump Exploded View – Rev A.1

24

Ref #

Part #

Description

Qty

Ref #

Part #

Description

Qty

1

CO3202001800

CAP

1

39

CO3200001700 PORT PLUG, AXD COMET PUMP

1

2

CO3609001400

SCREW, M8 X 55

4

40

CO2409009100

PISTON CHECK VALVE KIT,AXD UNL

1

3

CO3218032700

MANIFOLD

1

41

CO1210046000

O-RING

1

4

CO3202001800

CAP

1

42

CO2409008600

CHECK VALVE

1

5

CO1210004900

O-RING,OIL PLUG - WOBBLE

PUMP

6

43

CO1802019700

SPRING

1

6

SEE PART # 10

VALVE SEAT

6

44

CO3410031900

INJECTOR BODY KIT

1

7

CO3604002800

SUCTION/DEL. VALVE

6

45

CO1210004900

O-RING,OIL PLUG - WOBBLE PUMP

1

8

CO1802019200

SPRING, AXD

6

46

CO1210004000

O-RING, AXD

1

9

CO1205003300

VALVE CAGE, AXD

6

47

CO3410031100

INJECTOR BODY

1

10

CO1220004500

VALVE - AXD PUMP

6

48

CO2803043700

OUTLET FITTING, QUICK CONN.-

WO

1

11

CO0601027300

AXD SPACER

2

49

CO1215035400

THERMOVALVE

1

12

CO1210015100

O-RING, AXD3020

6

51

CO8102045000

FILTER WASHER

1

13

CO3202031100

VALVE CAP & O-RING

6

52

CO1223010800

GARDEN HOSE NUT

1

14

CO1817006400

HANDLE

1

53

SEE PART # 54

SPECIAL COUPLING - NLA

1

15

CO1215058500

REG.VALVE KIT & SEAT

1

54

CO2800051100

GARDEN HOSE TAIL W/WING NUT

1

16

CO1241005900

PACKING - GXD1617

3

55

SEE PART # 58

CHEM. COUPLING

1

17

CO0009036900

RING

3

56

CO3003002400

BALL FOR CHEMICAL INJECTOR

1

18

CO0009021900

RING(RETAINER) - WOBBLE

PUMP

3

57

CO1802018000

SPRING FOR CHEMICAL INJECTOR

1

19

CO1210035600

O-RING,SEAL CONTAINER -

WOBBLE

3

58

CO2803043500

CHEMICAL INJECTOR KIT

1

20

CO1241005700

BACK PACKING

3

59

CO3200001700

PORT PLUG, AXD COMET PUMP

1

21

CO0601030800

OIL SEAL SPACER

3

60

CO0001044200

DRIVESHAFT

1

22

CO0019005800

SEALING RING(OIL) - WOBBLE

PLA

3

61

CO1210042900

O-RING FOR AXD

1

23

CO3201002700

OIL SIGHT GLASS

1

62

CO0019003400

SEALING RING - AXD PUMP

1

24

CO1210004800

O-RING, 2.62 X 20.24MM

1

63

NOT AVAILABLE

SUPPORT

1

25

NOT AVAILABLE

PUMP CRANKCASE

1

64

CO3200007100

OIL PLUG - WOBBLE PUMP

1

26

CO2409015600

PISTON KIT

3

65

CO2811000400

WASHER - 268197

4

27

CO1802015300

SPRING, AXD

3

66

CO3607011900 SCREW - 268197

4

28

CO2409008900

PISTON - AXD3020G

3

29

CO0009022100

RING FOR AXD

3

30

CO0009022000

14MM RING FOR AXD

3

31

CO0438007600

BALL BEARING - AXD

1

32

CO0001054800

ECCENTRIC SHAFT - AXD

1

33

CO3609000500

SCREW, M8 X 20 - AXD

1

34

CO0436001700

BEARING

1

100 CO5025001400

VALVE KIT - AXD3020G

1

35

CO2816008800

THRUST BEARING

1

101 CO5019007700

SEAL KIT - AXD3020G

1

36

CO3609002800

SCREW M8 X 22

4

102 CO5019007900 SEAL KIT, AXD

1

Summary of Contents for BR1517ECO

Page 2: ...Hazard Signal Word Definitions 2 ...

Page 11: ...Pump Component Identification 11 Note Discard Shipping Plug and O ring BR1517ECO ...

Page 21: ...Parts Explosion BR1517ECO Rev A 1 21 ...

Page 23: ...Pump Exploded View Rev A 1 23 Part 790693 Comet AXD 1617E GH ...

Page 26: ...26 This page was intentionally left blank ...

Page 28: ...28 BRAVE 20195 S Diamond Lake Rd STE 100 Rogers MN 55374 ...