9

Initial Setup

Step Three:

Add Hydraulic Oil

to Reservoir

(continued)

5.

Disconnect the spark plug wire from the spark plug. This prevents the engine from

starting until the hydraulic pump and cylinder are completely filled with oil. Make

sure the spark plug wire is held away from the spark plug with string or other

nonconductive material.

6.

Push the valve control handle with one hand to the forward (extend) position

(towards the front of the cylinder). Pull on the starter grip recoil at least 20 times so

that hydraulic fluid has cycled through the pump.

7.

Reconnect the spark plug wire to the spark plug.

8.

Start engine and use control valve handle to extend and retract wedge five (5) times

to remove air from the high pressure lines.

9.

With wedge retracted, shut off engine.

10.

Check oil level again. Fill if necessary.

11.

Replace hydraulic oil fill/vent cap.

WARNING:

NEVER remove the hydraulic oil fill cap when the engine is running or

hot. Hot oil can escape causing severe burns. Allow log splitter to cool completely

before removing hydraulic oil fill cap.

Note:

If the log splitter will be run for long periods of time in outdoor temperatures

above 70°F, we recommend changing the hydraulic oil to DEXRON III.

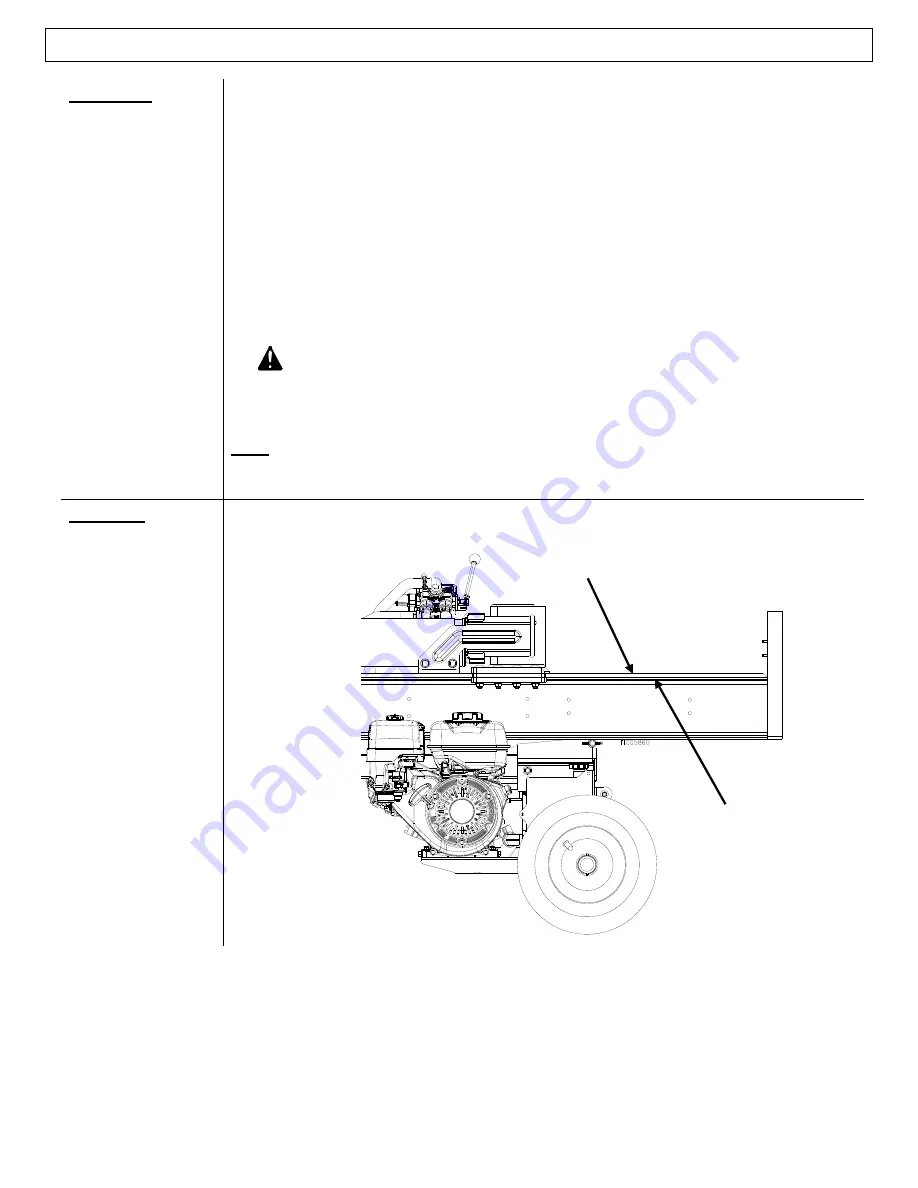

Step Four:

Lubricate Beam

Lubricate the surface of the beam with grease.

This will help prevent wear between the

wedge keepers and the beam.

Apply grease to the top of the beam and underneath the edge of the

beam, where the wear pads travel.