SERIES 762 BIDIRECTIONAL SLURRY KNIFE GATE VALVES

Installation, Operation, and Maintenance Manual

25 of 30

© 2021 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

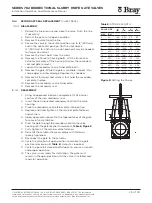

Figure 7:

Gate Disassembly

Figure 8:

Gate Removal

14.3

GATE REPLACEMENT

14.3.1 1. Relieve the line pressure and open the valve. Flush the line if

necessary.

2. Remove the cylinder port tubing and vent the air inside the

cylinder if the valve with Pneumatic operated.

3. Remove the seat as per seat replacement procedure.

4. Lock the gate in opened position using a suitable locking pin

in the holes provided.

5. If the valves are supplied with bellows, ensure stem is not

rotated, as rotation will damage the bellows.

6. Disassemble the super structure by removing the fasteners

with body.

7. Lift the damaged/old gate & superstructure from the body

assembly using suitable sling strapped below the base plate

of superstructure. An overhead hoist may be required for

larger size valves.

8. Lay the superstructure & old gate assembly in horizontal

position & disconnect the stem/Piston rod from the gate by

removing the clevis bolts & nuts.

9. Remove the secondary seal, wiper and retainer and inspect

the seal for suitability to reuse.

10. Lubricate the new gate and install it in body carefully.

11. Insert the secondary seal back into the packing chamber.

12. Re-attach the wiper and secondary seal retainer onto the

valve body.

13. Tighten the secondary seal retainer bolts.

14. Inject the recommended lubricant at the grease nipple.

15. Mount the actuator and super structure on the valve.

16. Hand tighten the body bolting to the superstructure.

17. Tighten the actuator bolting.

18. Connect the gate and stem by clevis bolts and nuts.

19. Lower the stem by rotating the hand wheel clockwise (or

by applying air gradually for cylinder operated valves) while

holding the stem and fasten the stem to the gate with bolts

and nuts.

20.Operate the valve for a few cycles and then tighten the body

to superstructure bolting as per the recommended torque as

per Table Install the seat as per above procedure.

21. Adjust and ensure the gate positions from top of the body

according to

Table 2

on page 15.

14.3.2 Changing or repair of other valve parts by users is not

recommended; please contact Bray for any further advice and

assistance.

(continued)