3

Small Weather Shield

-

Installation, Operation & Maintenance Manual Continued

Special Tools Needed:

• 8 mm (5/16 in.) open-end wrench

• 6 mm (1/4 in.) flat-blade screwdriver

• No. 1 Phillips screwdriver

• No. 2 Phillips screwdriver

21 mm and 22 mm open end wrench

(or two adjustable wrenches)

Parts Included:

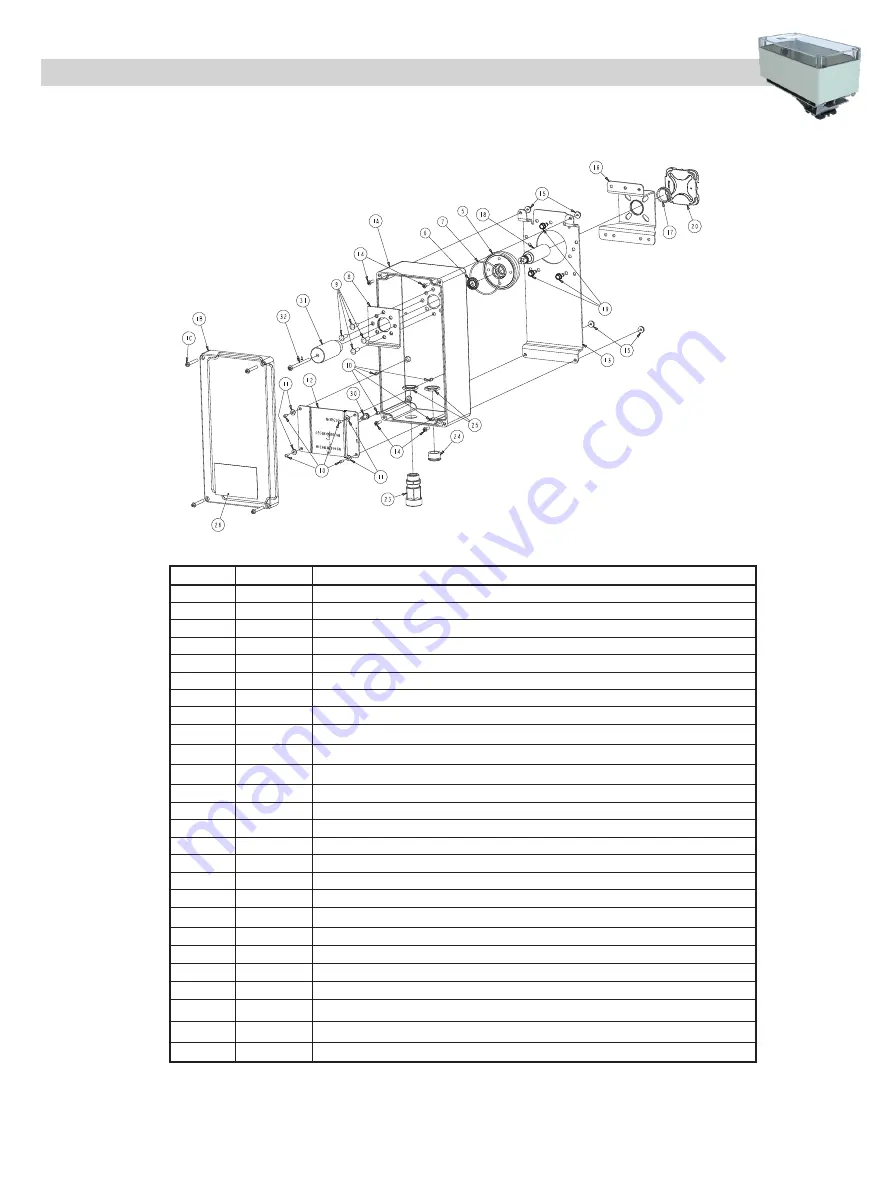

Table 1: Parts Included in Small Weather Shield Enclosure Kits

Callout

Quantity

Description

1A

1

Base, enclosure

1B

1

Clear enclosure cover

1C

4

Screw, cover (factory-installed)

5

1

Bearing, seal carrier (factory-installed)

6

1

Seal, lip (factory-installed)

7

1

O-Ring, RoHS (factory-installed)

8

1

Plate, inner (factory-installed)

9

4

Screw, button head Torx, RoHS (factory-installed)

10

2

4

Screw, M3 x 0.5 x 8 mm long, Phillips, oval countersink

11

2

4

Washer, flat, M4, plain steel, 4.3 mm ID x 9.0 mm OD x 0.8 mm

12

2

1

Bracket, Anti-rotation, weather shield

13

1

Bracket, mounting

14

4

Screw, machine, #6-32 x 1/2 in. long, cross-recessed pan head, RoHS

15

4

Nut, #6-32 hex, flanged, serrated tooth, RoHS

16

1

Bracket, valve

17

1

Bearing, plastic, flanged, split, 20 mm ID, RoHS (factory-installed)

18

1

Shaft, valve

19

3

Screw, tapping, hex washer head, type F, RoHS

Figure 2: Parts Included (See Table 1)

20

1

Thermal barrier

23

2

Gland, cable, PG11 to 1/2 in. NPSL

24

1

Cap plug, PG11 with O-Ring, RoHS

25

2

Nut, hex, single chamfer, PG11

26

1

Label (factory-installed)

30

2

1

Screw, tapping, hex washer head, type SW, RoHS

31

2

1

Shaft, valve, 1 in. diameter

32

2

1

Screw, M4 x 0.7 x 60 mm long, Torx.slotted pan head

1. We recommend using a 1/2 in. liquid-tight conduit and 1/2 in. National Pipe Thread (NPT) liquid-tight fittings (purchased

locally) to terminate the control wiring to the weather shield enclosure strain relief conduit fittings.