11

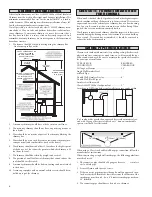

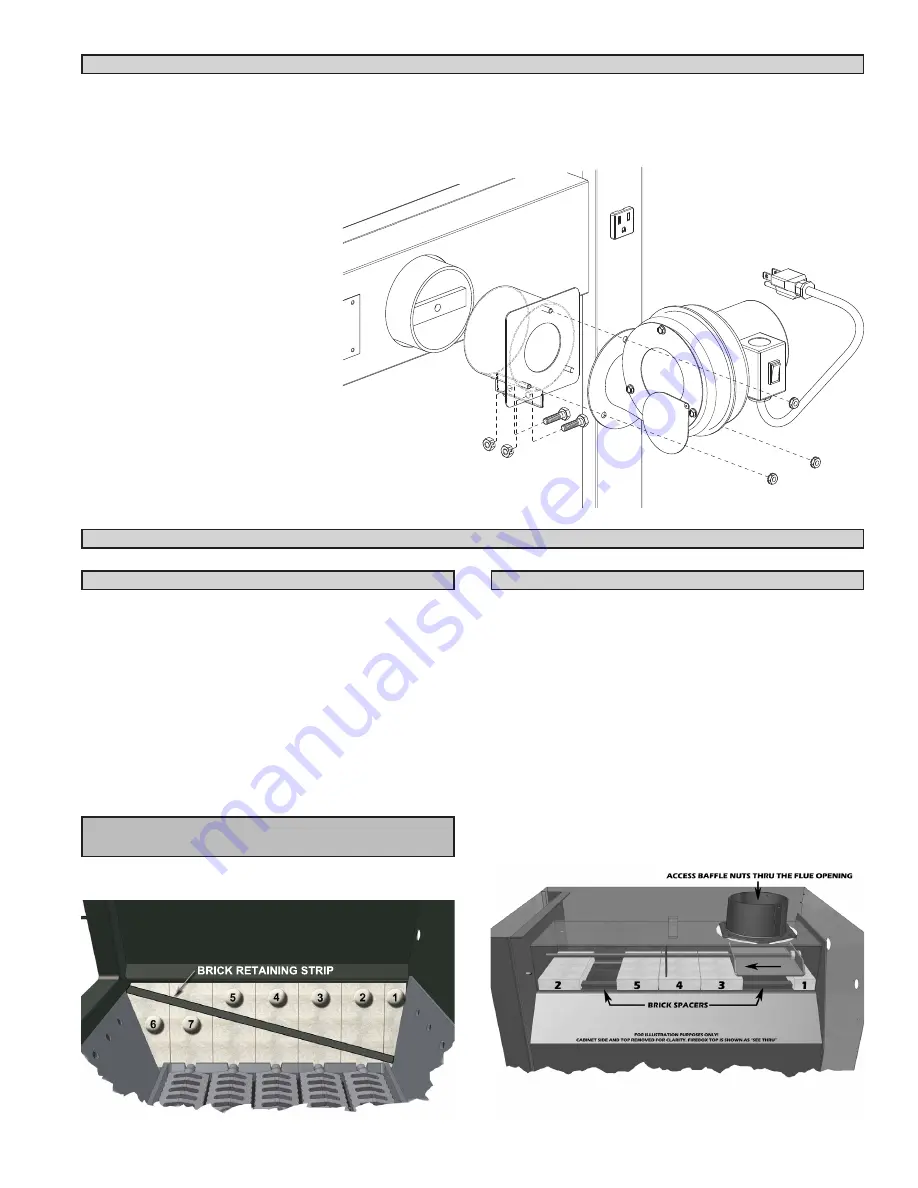

FIREBOX BRICK REPLACEMENT

This furnace comes from the factory with the firebrick installed. How

-

ever, if brick replacement is necessary, follow these instructions. Be

-

fore furnace operation, remove the brick retaining strip. This piece is

used during shipping to reduce brick damage.

For model AAF747, there are 6 full brick and 1 half brick per side.

Install the half brick first by putting the bottom of the brick in first

and let it rest against the firebox side and fire grates. Then slide it to

the rear. After that, install the #2, #3, #4, #5 & #6 brick, sliding the

6th brick forward to allow for the 7th brick. Repeat for opposite side.

NOTE: Prior to operation, be sure to remove the brick retaining

strips.

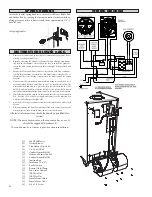

FORCED DRAFT BLOWER - 69189

Using two 1/4-20 x 1” bolts and nuts, attach the draft blower adapter

to the draft tube on the front of the furnace. Then mount and secure

the draft blower to the adapter with the three 10-24 Kep nuts. Plug the

blower into the outlet on the front of the furnace.

(1) Draft Blower

(1) Draft Blower Adapter

(2) 1/4-20 x 1 Hex Bolt

(2) 1/4-20 Lock Nut

(3) 10-24 Kep Nut

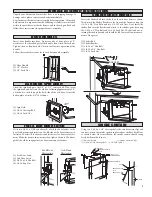

FIREBRICK AND BAFFLE REPLACEMENT

BAFFLE/BRICK REPLACEMENT

If baffle replacement is necessary, slide the baffle out until you can ac

-

cess the nuts thru the flue outlet. Once the nuts have been removed,

slide the baffle off the rod and thru the opening in the firebrick. You

may have to remove one of the firebrick to make baffle removal easier.

For model AAF747, there are 4 full brick and 1 half brick in the top of

the furnace. Install the brick by inserting one end of the brick angled

upward and then allowing the opposite end to rest on the firebox lip.

Lay the brick between the spacer and firebox back. Slide the baffle to

the rear and let it rest on that half brick. After installing brick #2 in

the front, install #3 and slide it under the baffle. Finally install bricks

#4 and #5.

Summary of Contents for SF747

Page 2: ...2...