14

TROUBLE SHOOTING AND PROBLEM SOLVING

1. Problem:

Smoke puffs from furnace

Solution:

A. Check chimney draft. Check for blocked chimney or flue pipe.

Use mirror to check chimney clearance.

B. Check ash pit — if it is too full, empty.

C. Make sure furnace room is not too airtight.

D. Make sure all of chimney mortar connections are airtight.

E. Check ash drawer. Make sure it’s airtight.

F. Check chimney for possible down-draft caused by taller sur

-

rounding trees or objects. Correct with proper chimney vent

cap.

G. Check the possibility of a cold chimney forcing cool gases

backward. Remedied by properly insulating chimney with

non-combustible liner — non-combustible insulation.

H. Fuel may be too green.

I. Make sure no other fuel burning devices are connected to the

chimney impairing the draft.

J. Check chimney draft, it should be .06 inches of water column.

This service is provided by a certified chimney sweep.

2. Problem:

Inadequate heat being delivered to your home

Solution:

A. Check home insulation — is it adequate?

B. Check hook-up to furnace — is it installed correctly?

C. Cool air inlet may be inadequate or furnace room too airtight.

D. Your wood fuel may be too low grade. Hardwoods are recom

-

mended.

E. Make sure your hot air duct (and other duct work) is airtight.

F. If furnace room is warm but your home isn’t, check back draft

dampers.

G. Is air to the blower available?

3. Problem:

Excess smoke or flames coming out door when refueling

Solution:

A. Wait 15 seconds and open door SLOWLY — then refuel.

B. Check length of flue pipe to chimney. Your unit should be

within six (6) feet of your chimney.

C. Make sure chimney cap is not too close to the top of the chimney.

D. Check chimney draft — make sure chimney flue pipe is clean

and chimney is of adequate height.

E. Make sure you’re not suffocating the fire with excessive amounts

of unburned wood.

F. Slide baffle should be pulled out prior to load door opening.

4. Problem:

Distribution blower vibrating

Solution:

A. Tighten blower wheel to motor shaft.

B. Check for bad fan bearings.

5. Problem:

Distribution blower continues to run or will not run

Solution:

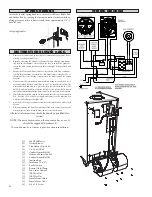

A. Check fan limit or heat sensor and cable.

B. Check to see that blower is properly wired.

(See Wiring and Assembly Instructions).

C. Check fuse box or power source.

D. Check power supply.

6. Problem:

Draft blower continues to run or will not run

Solution:

A. Check wiring.

B. Check thermostat or thermostat wire for short.

C. Make sure temperature is calling for heat.

7. Problem:

Odor from first fire

Solution:

A. The odor from new steel should disappear in a few hours.

B. If the odor remains, call you dealer immediately. A bad weld

can cause a fume leak.

8. Problem:

Excessive Creosote

Solution:

A. Check the grade of wood you are burning.

B. Make sure your unit is serviced by its own proper chimney.

C. Check length of flue pipe and its connections.

D. Make sure you are burning the smallest, hottest fire to adequately

heat your home.

E. Also see Solutions to Problem one.

9. Problem:

If the fire goes out or does not hold over night

Solution:

A. Poor Draft.

B. Incorrect damper settings.

C. Improper firing methods if burning coal.

D. More combustion air needed.

E. Coal not sized to the furnace. We recommend 1” to 3” diameter

pieces of coal.

F. Ashes, if allowed to accumulate in the ash pit, will not allow

passage of the required air for combustion. Keep ash pit clean.

G. This furnace is not to be used with an automatic stoker unless

so certified.

Summary of Contents for SF747

Page 2: ...2...