19

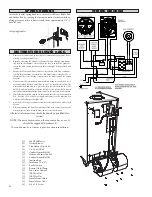

Only when the coal is burned down to half its original depth it

is time to add fresh coal. When doing so, open the stove pipe

damper and turn the thermostat damper to high, which will

allow the fire to burn off any accumulated gases. Open the

feed door, and with a small rake, hoe, or hooked poker pull

the glowing coals to the front of the firebox. Try not to disturb

the fire too much. Next, add a fresh charge to the back being

careful not to seal off the top. Close the feed door, but leave the

spin damper (or thermostat) open for a few minutes until the

volatile gases have burned off. It is not necessary to shake down

the ashes each time you refuel the furnace. Experience will be

your best teacher.

BANKING THE FIRE:

For extended operation, such as overnight, the fire will need to

be banked. To do so heap coal up along the sides and back of

the firebox so that the fire gradually burns it over a longer pe

-

riod of time. The intensity of the fire will also be reduced with

-

out letting it go out. Follow the same procedure as for refueling.

If possible, avoid shaking, as a heavier layer of ash will help

reduce the intensity of the fire during this time. After loading,

let the fire establish itself for about 30 minutes. Then close your

damper and automatic control to the point where the house

does not become too cold. It is important that you begin bank

-

ing early enough before retiring or leaving that you can make

necessary adjustments after the fire is well established.

To revive a coal fire that is almost out, (1) open the ash door

and stove pipe damper and close the spin damper under the

door to get a good draft through the grate. (2) place a thin layer

of dry coal over the entire top of the fire. DO NOT POKE OR

SHAKE THE FIRE AT THIS TIME! (3) after the fresh coal has

become well ignited shake the grate (just a little), refuel.

BULLETIN RC454

A GUIDE TO BURNING COAL IN YOUR FURNACE

DO NOT burn coke, charcoal, high volatile bituminous coal,

sub bituminous, lignite or cannel coal (sometimes called chan

-

nel coal or candle coal).

NEVER burn wax or chemically impregnated sawdust logs -

their intended use is for fireplaces only.

NEVER fill the stove or furnace above the firebrick or cast iron

liner.

Summary of Contents for SF747

Page 2: ...2...