9

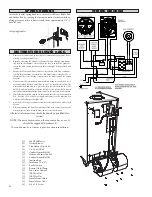

FURNACE ASSEMBLY INSTRUCTIONS

Unpack your Furnace and insure that there is no shipping damage. If

damage exists, please contact your dealer immediately.

Your furnace will require some assembly before operation. All needed

hardware and components for the following assemblies are included

within the parts boxes inside the furnace and in the ash pan. Read and

follow these instructions for proper furnace assembly.

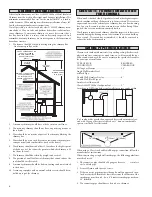

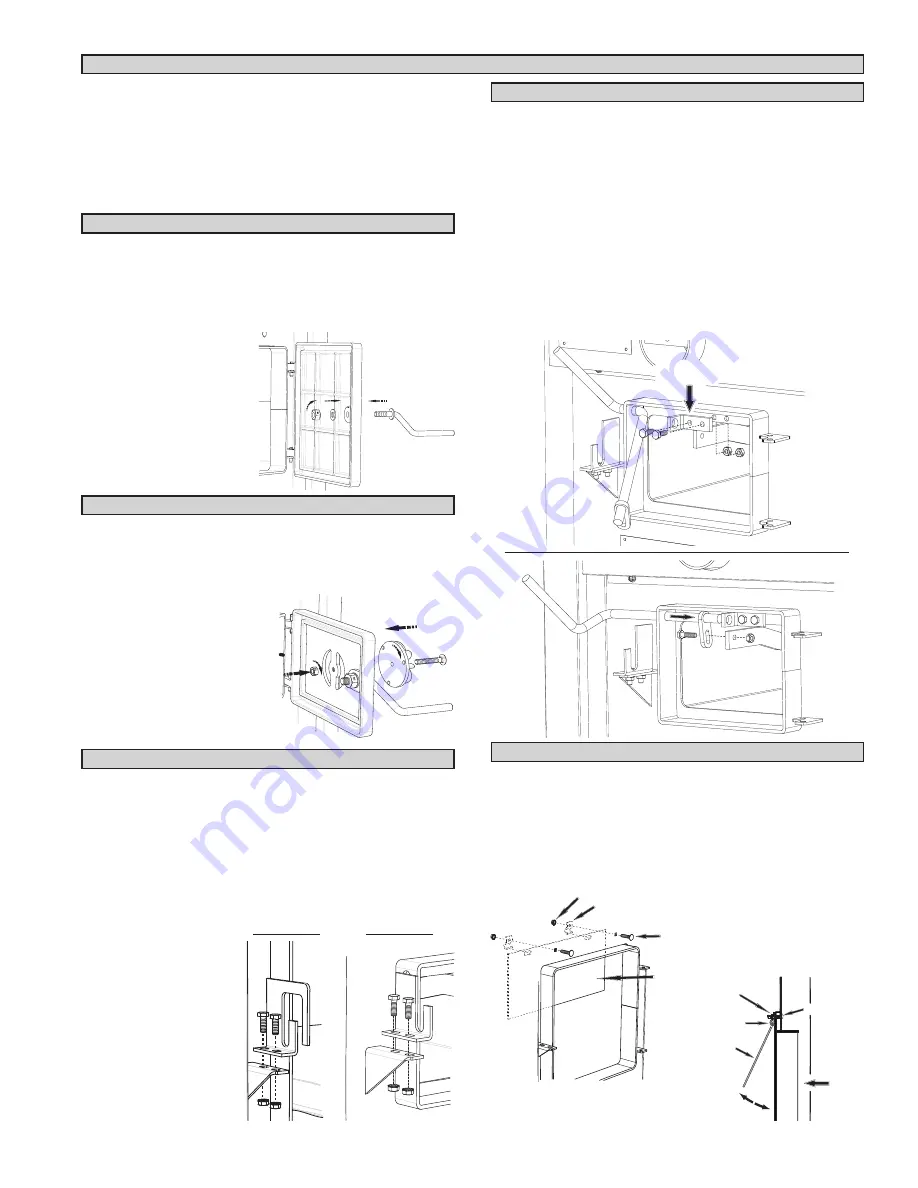

DOOR HANDLES

Insert door handle into door. From rear side of door, place a 1/2”

washer over the threaded part of the handle, then attach the lock nut.

Tighten the nut, then back off 1/4 turn to allow free operation of the

handle.

Follow these same directions for the ash door handle assembly.

(2) Door Handle

(2) 1/2” Washer

(2) 1/2” Lock Nut

ASH DOOR SPIN DRAFT

Screw the spin draft onto the 3/8” x 2-1/2” carriage bolt. Then screw

the spin draft and bolt into the ash door allowing approximately 1/2”

of the bolt to stick through the back side of the ash door. Secure the

bolt in place with the 3/8”-16 lock nut.

(1) Spin Draft

(1) 3/8-16 Carriage Bolt

(1) 3/8-16 Lock Nut

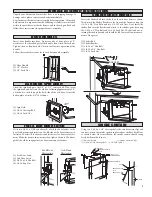

FUEL & ASH DOOR LATCH

With two 1/4-20 x 3/4 hex bolts each, attach the door latches to the

door latch mounting brackets on the left side of the door frames as il

-

lustrated. The slots in the brackets and latches are for door seal adjust

-

ment. Make the proper adjustments, then tighten the nuts. The door’s

gasket should be snug against the door frame on the furnace.

Feed Door

Illustration

Ash Door

Illustration

(1) Feed Door Latch

(1) Ash Door Latch

(4) 1/4-20 x 3/4 Hex Bolt

(4) 1/4-20 Kep Nut

SHAKER GRATE HANDLE

BRACKET

Insert the Shaker Rod into the hole on the ash door frame as shown.

Then attach the Shaker Bracket to the front of the furnace using two

1/4-20 x 3/4” Hex Bolts and two 1/4-20 Lock Nuts. Next, insert the

shaker Rod into the bracket and attach to the shaker grate bar using

the 1/4-20 x 1” Hex Bolt and a 1/4-20 Lock Nut. The bolt and nut re

-

taining the shaker bar and rod should be left loose to allow free move

-

ment of the grates.

(1) Shaker Rod

(1) Shaker Bracket

(1) 1/4-20 x 1” Hex Bolt

(2) 1/4-20 x 3/4” Hex Bolt

(3) 1/4-20 Lock Nut

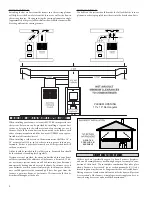

SMOKE CURTAIN

FRONT

SMOKE CURTAIN

SMOKE CURTAIN

CLIP

NUT

BOLT

1/4-20 NUT

SMOKE CURTAIN

CLIP

1/4-20 x 1-1/4

CARRIAGE BOLT

SMOKE CURTAIN

Using two 1/4-20 x 1-1/4” Carriage bolts, the smoke curtain clips and

two nuts, attach the smoke curtain in place above the Fuel Feed Door

as shown below. After installation, the smoke curtain should swing

freely back into the furnace.

(1) Smoke Curtain

(2) Smoke Curtain Clips

(2) 1/4-20 x 1-1/4 Carriage Bolt (2) 1/4-20 Kep Nut

Summary of Contents for SF747

Page 2: ...2...