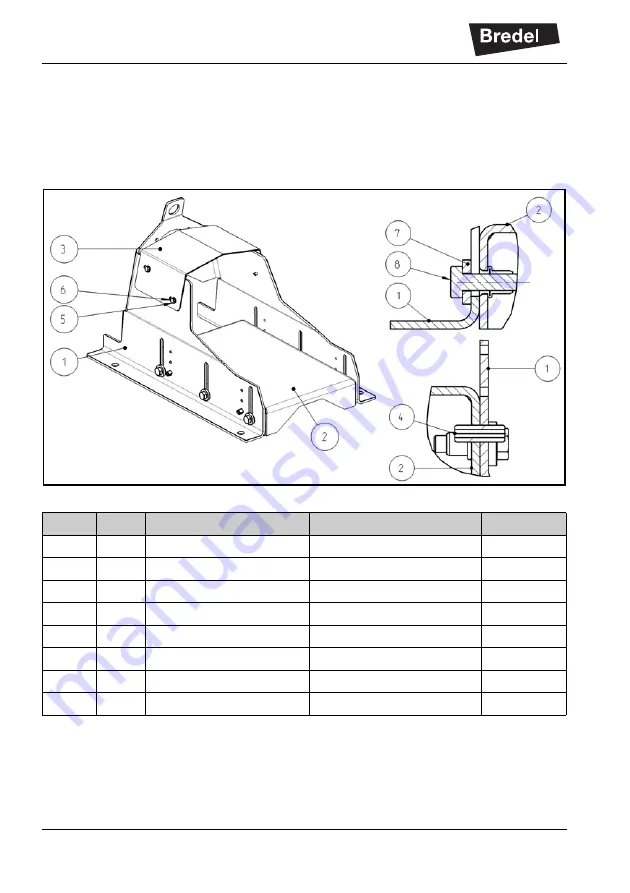

SPECIFICATIONS

22

6

SPECIFICATIONS

6.1

Parts list

6.1.1

Support Set 10-20

Pos.

Qty.

Description

Size

Material

1

1

Pump support

steel

2

1

Gearbox support

steel

3

1

Coupling guard

steel

4

4

Pin

ISO 8750 - 8 x 24

steel

5

4

Plain washer

M5

steel

6

4

Hexagonal head screw

M5 x 12

steel

7

6

Thick flat washer

M8

steel

8

6

Hexagonal head screw

M8 x 30

steel