14

6 Maintenance

Careful maintenance and, in particular, scrupulous cleaning are essential for problem-free operation

of the pulsation damper.

Before carrying out any maintenance to the pulsation damper, please thoroughly acquaint yourself

with the directives in the chapter

.

Any repair to the pulsation damper is to be carried out by properly skilled and authorised users

only.

After cleaning and maintenance work, do not use the pulsation damper until all parts that have

been removed, are reinstalled correctly.

WARNING

Release the pressure from the pulsation damper by means of the ball valve near the

pressure-relief valve, before starting on any work to the pulsation damper.

WARNING

Protect your hands and face from any dangerous substances when handling or

examining the pulsation damper hose.

CAUTION

After maintenance has been carried out, and before switching the pump back on,

ensure that all valves present in the pipe work are opened.

6.1

Cleaning the pulsation damper hose internally

The inside of the pulsation damper hose is easily cleaned by flushing the pump and pulsation damper

with clean water. If a cleaning fluid is added to the water, it must be checked that th e hose liner

material is resistant to that.

With many products to be pumped, it is necessary to clean the pulsation damper hose

immediately once the pump is stopped, to avoid solidification and hardening of the

product within the hose.

6.2

Removing the pulsation damper hose

1. Disconnect the electrical supply from the corresponding pump and close any valves to minimise

product loss.

2. Position a tray under the pulsation damper. This tray must be sufficiently large to collect all liquid

product inside the pulsation damper.

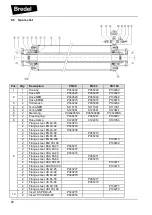

3. Release all pressure from the pulsation damper using the ball valve (pos. 17).

WARNING

If the pulsation damper hose is cracked or worn, liquid product to be pumped may

escape via the ball valve (pos. 17). Therefore, take the necessary safety precautions.