21

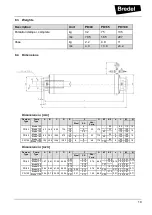

Pos.

Qty.

Description

PD/40

PD/65

PD/100

2

Insert, PP PD40-25

P040290

2

Insert, PVDF 40-25

P040280

2

Insert, SS PD 40-32

P040295

2

Insert, PVC PD 40-32

P040296

2

Insert, PP PD 40-32

P040291

2

Insert, PVDF 40-32

P040281

2

Insert, SS PD 40-40

P040211

2

Insert, PVC PD 40-40

P040212

2

Insert, PP PD40-40

P040292

2

Insert, PVDF PD40-40

P040282

2

Insert, SS PD 65-50

P065215

2

Insert, PVC PD 65-50

P065216

2

Insert, PP PD 65-50

P065290

2

Insert, PVDF 65-50

P065280

2

Insert, Steel PD 65-65

P065210

2

Insert, SS PD 65-65

P065211

2

Insert, PVC PD 65-65

P065212

2

Insert, PP PD 65-65

P065292

2

Insert, PVDF 65-65

P065282

2

Insert, Steel PD 100-80

P100214

2

Insert, SS PD 100-80

P100215

2

Insert, PVC PD 100-80

P100216

2

Insert, PP PD 100-80

P100290

2

Insert, PVDF 100-80

P100280

2

Insert, Steel PD 100-100

P100210

2

Insert, SS PD 100-100

P100211

2

Insert, PVC PD 100-100

P100212

2

Insert, PP PD 100-100

P100292

2

Insert, PVDF 100-100

P100282

11

8

Bolt M8 x 20

F111071

8

Bolt M10 x 25

F111096

8

Bolt M12 x 30

F111130

12

8

Washer M8, Spring Lock

F336011

8

Washer M10, Spring Lock

F336012

8

Washer M12, Spring Lock

F336013

13

1

Nipple

A132511

A121004

A121004

14

1

Cros

s piece G1/2”

A123003

A123003

A123003

15

1

Reducing ring G1/2”x 3/8”

A122006

A122006

A122006

16

1

Reducing ring G1/2”x 1/4”

A122005

A122005

A122005

17

1

Ball valve

G3/8”

A106002

A106002

A106002

18

1

Nipple

G3/8”

A125005

A125005

A125005

19

1

Safety val

ve G1/2”

A210003

A210003

A210003

20

1

Pressure gauge 0-25 bar

A220001

A220001

A220001

21

1

Stop

A124514

A124516

A124516

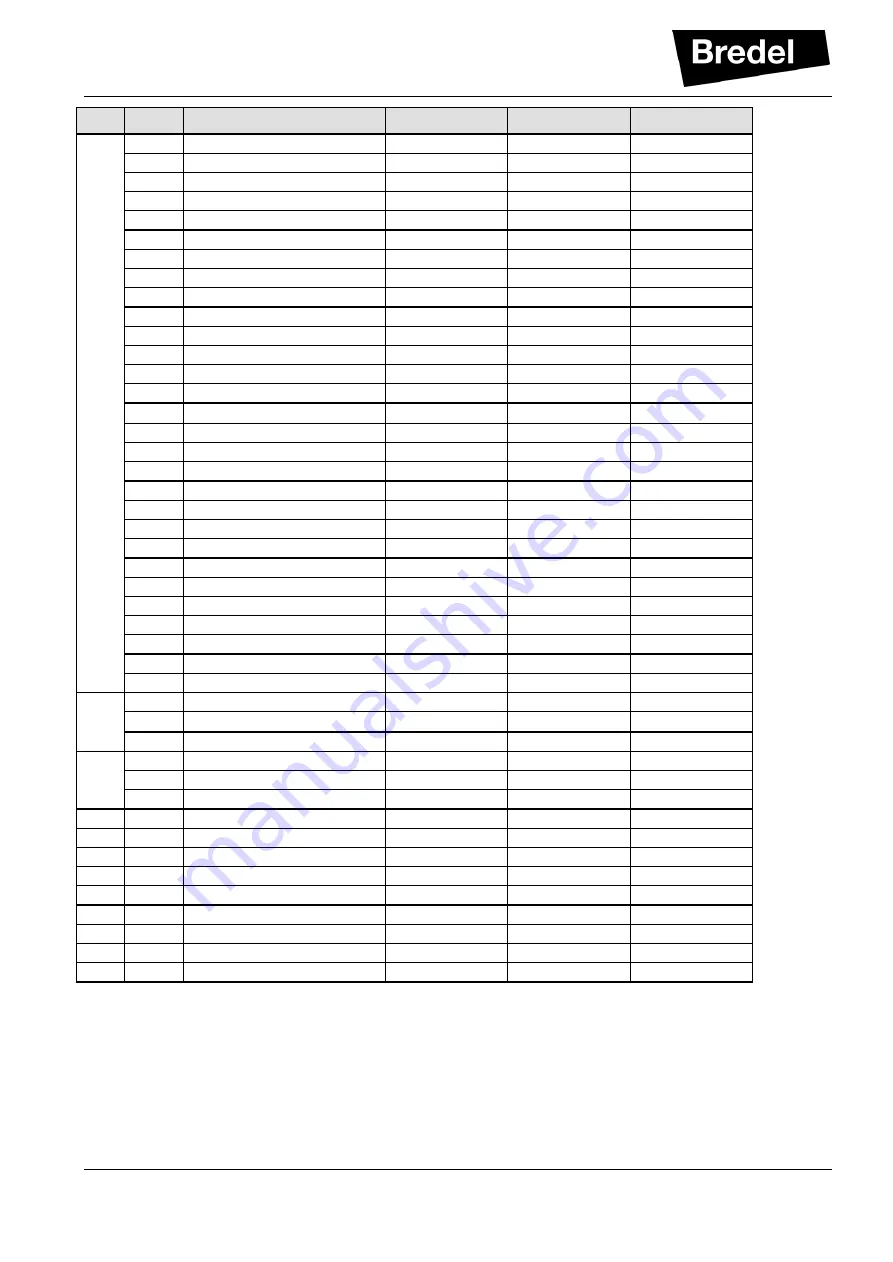

1.2 Surface treatment

After surface preparation, one layer of two-component acrylate is used for surface protection.

Standard color is RAL 3011, however other colors are optional. Contact your Bredel

representative for details on surface treatment.

All galvanized parts, excluding fasteners, will have an electrolytic zinc layer of 15 -20 microns.