9

When the discharge pressure drops, the pulsation damper hose contracts and compensates for the

released volume of the pressing shoe in the discharge line. The fluid deceleration is minimised and

the pulse will be reduced.

Depending on the application and size the damper can reduce the pulse by 50-90%. The damper is

most effective at a discharge pressure of 500 kPa or above. The pulsation dampers can be

pressurized up to 1600 kPa. The pulsation dampers are safeguarded for over-pressure by a

pressure-relief valve.

4.3

Pulsation damper hose

The pulsation damper hose liner material should be chemically resistant to the product to be pumped.

Dependent on the specific requirements of your application, a matching hose should be selected.

A. Outer extruded layer made of natural rubber

B. Four nylon reinforcement layers

C. Inner extruded liner

For each pulsation damper, various hose types are available. The material of the inner liner of the

hose determines the hose type. Each hose type is marked by a unique colour code.

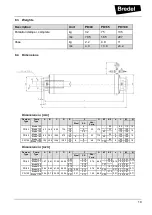

Hose

type

M aterial

Colour

code

Article number:

PD/40

PD/65

PD/100

NR

Natural rubber Purple

P040020

P065020

P100020

NBR

Nitrile rubber

Yellow

P040040

P065040

P100040

EPDM

EPDM

Red

P040075

P065075

P100075

Consult your Bredel representative for Hose Pumps for more

detailed information about the chemical and temperature resistance

of pulsation damper hoses.

Store the pulsation damper hose in a cool, dry place and do not

subject it to sunlight.