12

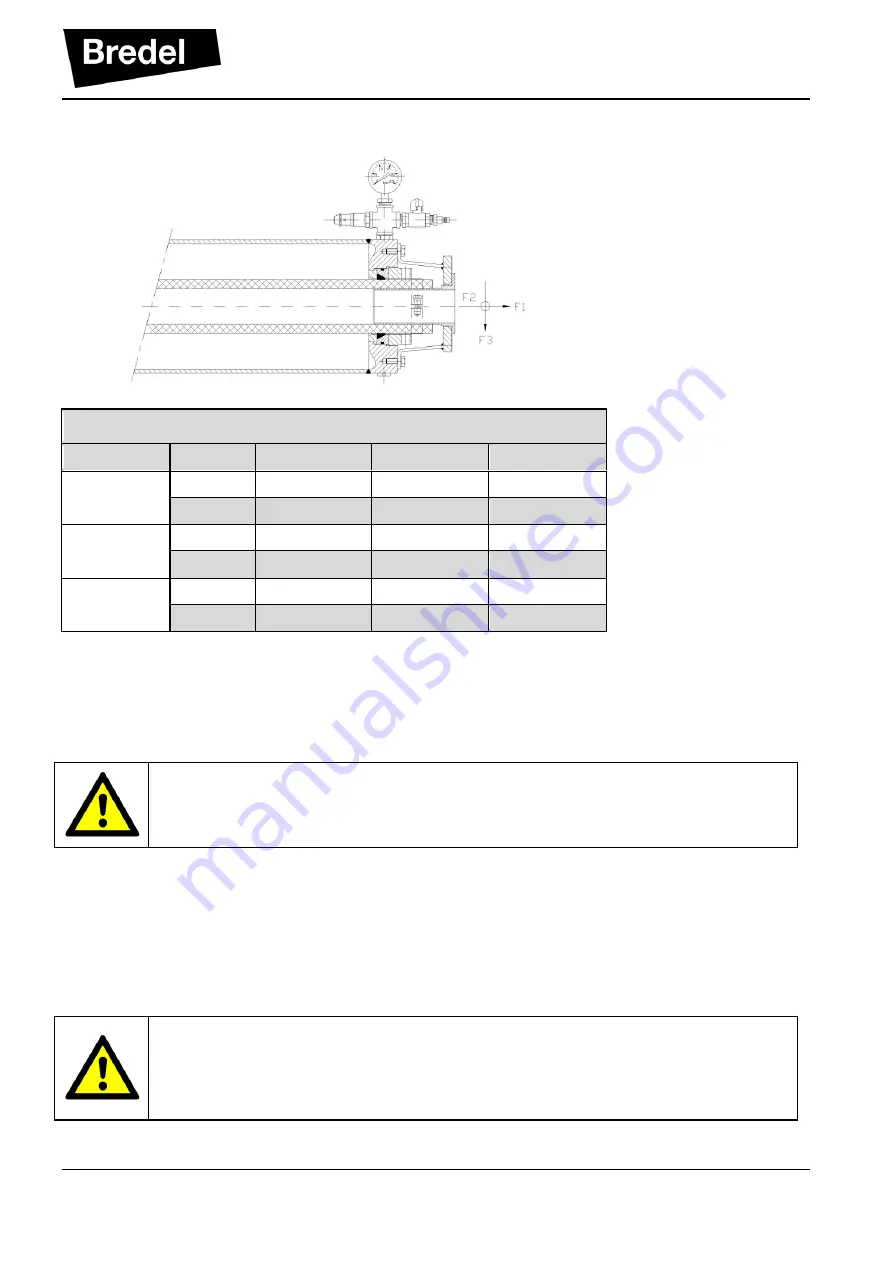

Avoid too heavy loads on the flanges. The maximum forces are given in the table below:

M aximum flange loads

Force

Unit

PD/40

PD/65

PD/100

F1

N

1000

1400

2000

lbf

225

315

450

F2

N

500

700

1000

lbf

112

157

225

F3

N

200

300

400

lbf

45

67

90

5.4

Lifting and moving the pulsation damper

To lift, move and position the pulsation damper, suitable hoisting belts must be used. The best place

to attach the hoisting belts is immediately behind both flanges of the pulsation damper. Keep in mind

the pulsation damper’s weight. For weights see also paragraph

.

WARNING

If the pulsation damper is to be lifted, ensure that all safety regulations for lifting

movements are adhered to and that the lifting is carrie d out by qualified personnel

only.

5.5

Setting the pulsation damper pressure level for operation

The pulsation damper air or nitrogen pressure level must be set. This setting for maximum pulse

reduction depends on the process condition. Therefore the setting can only be obtained when the

pump is running at operating conditions.

It is advised to check the pressure relief valve functioning with each installation, hose replacement or

annually (which comes first). (See paragraph

6.4 Checking the Pressure relief valve

CAUTION

Consider the maximum allowable pressure. The maximum allowable pressure can

either be determined by the pulsation damper, pump or process. Exceeding the

maximum allowable pressure may lead to serious injuries or damage to the pump and

the environment.