16

15. Pressurize the vessel to 1400 kPa (14 bar, 203 psi) above atmospheric. By pressurizing the hose

will be stretched outwards, forcing the hose ends over the inserts.

16. Close the ball valve.

17.

Tighten both hose clamps (pos. 8) with the proper torque values.

The minimum required torque values as advised (see paragraph

)

cannot always be realized in the field. This is due to the unknown friction between

tightening bolt and clamp. Especially in case of used stainless steel clamps that are

not properly greased. In such case the applied bolting torque does not reflect the

required clamping force of the hose clamp.

So in case the minimum specified torque values are not sufficient it is advised to

increase the bolt torque until a sealed situation is obtained. Here the absolute torque

value is of less importance (although maximum applied bolting torques should remain

within the range specified (see paragraph

). It is advised to tighten

the clamp until the outside diameter of the clamp is between 0 to 2 mm (0 to 0.08 inch)

below the outside diameter of the PD hose in unclamped condition.

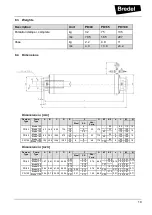

PD/40

PD/65

PD/100

Advised Clamp OD

[mm]

69

– 71

98

– 100

138

– 140

[inch]

2.72

– 2.80 3.86 – 3.94 5.43 – 5.51

The complete PD hose replacement procedure can also be done with the PD outside

the piping system, provided that the inserts are locked by installing an additional flange

on both sides of the pulsation damper flanges and external gas pressure (up to

1600 kPa, 16 bar, 232 psi above atmospheric) can be applied.

6.4

Checking the Pressure relief valve

It is advised to check the pressure relief valve functioning with each installation, hose replacement or

annually (which comes first).

1. Check all parts to be installed for any damage and replace when necessar y.

2. Make sure the pulsation damper is fully assembled and installed in the process piping. (If testing is

done with a standalone pulsation damper the inserts should be blocked by fitting additional

flanges on both flanges of the pulsation damper.)

3. Apply pressure to the pulsation damper by carefully opening the ball valve. The procedure for

applying the pressure is described in the paragraph “Setting the pulsation damper pressure level

for operation”.

4. Above 1600 kPa (16 bar, 232 psi), the pressure relief valve should open, keeping the pressure

from rising further. The proofs the relief valve is fit for duty.

CAUTION

Do not pressurize the pulsation damper if the inserts are not secured. Securing the

insert can be done by installing an additional flange on both flanges of the pulsation

damper or by installing the pulsation damper into the pipe system.

CAUTION

If you want to check the function of the pressure-relief valve, apply pressure to the

vessel of 1600 kPa (16 bar, 232 psi). The valve should automatically open. Relieve the

pressure. Replace the pressure-relief valve if it does not open before reaching

1700 kPa (17 bar, 246 psi) pressure