4

Model:

VFB80HLED2

PREPARATION

Tools Required for Assembly (not included): Hammer,

Flathead Screwdriver, Wire Nuts, Nails, Duct Tape,

Phillips Head Screwdriver, Utility Knife

Helpful Tools (not included): Electric Drill, Drill Bits

WARNING: Turn off electricity at breaker box

before beginning installation.

Carefully remove unit from carton.

Check area above installation location to be sure that

wiring can run to the planned location and that duct

proper ventilation.

Inspect duct work and wiring before proceeding with

installation.

Before installation, provide inspection and future

maintenance access at a location that will not

interfere with installation work.

You may need the help of a second person to install

this fan: one person on the attic side and one on the

room side.

Note: Installations may vary depending on how the

previous bath fan was installed. Supplies necessary

for the installation of your bath fan are not all included.

However, most are available at your local home

improvement or hardware store.

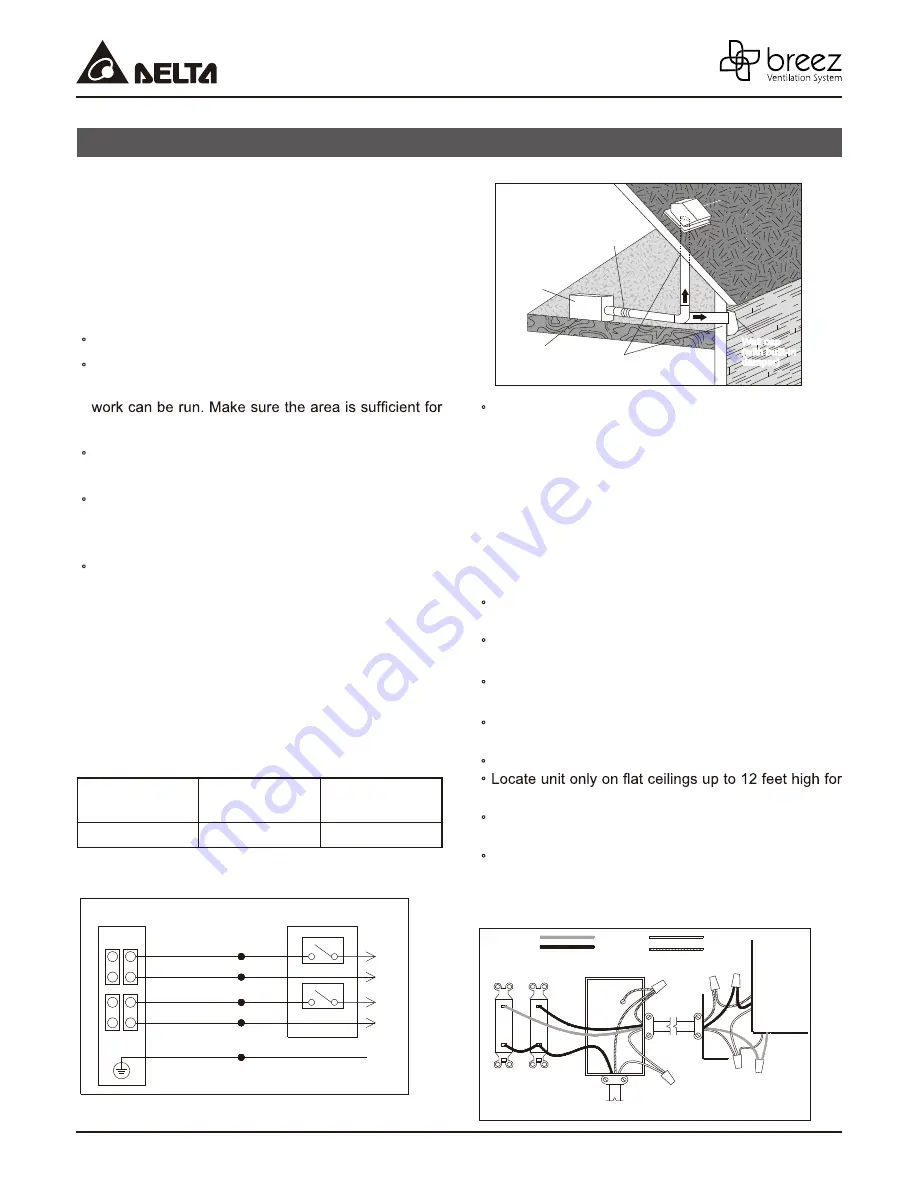

WIRING DIAGRAM

DIMENSION REQUIREMENTS

Housing

Dimension (L)

Housing

Dimension (W)

Housing

Dimension (H)

8 in.

8.25 in.

5.75 in.

Proper insulation around the fan to minimize building

heat loss and gain. The ducting from this fan to the

outside of the building has a strong effect on the air

flow, noise and energy use of the fan. Use the

shortest, straightest duct routing possible for best

performance, and avoid installing the fan with smaller

ducts than recommended. Insulation around the

ducts can reduce energy loss and inhibit mold growth.

Fans installed with existing ducts may not achieve

their rated air flow.

Locate unit above (GFCI-protected circuit required)

or within 5 feet of the shower head.

Locate unit away from heating or cooling sources

which can affect humidity levels.

Do not locate near window. Unit may respond to the

outdoor humidity level.

Unit must be installed in ceiling to properly sense

moisture.

proper sensing.

Use a roof cap or wall cap

that has a built-in damper

to reduce backdrafts.

BLACK

ON/OFF SWITCH

(purchase separately)

SWITCH BOX

120 VAC

LINE IN

WHITE

GROUND

(bare)

POWER

SWITCH

WIRING

PLATE

LIGHT

SWITCH

BLUE

OFF

ON

L

N

POWER SWITCH

JUNCTION BOX

SWITCH BOX

WHITE

BLACK

GREEN

GRD

OFF

ON

L

N

LIGHT SWITCH

WHITE

RED

BLACK

ON/OFF SWITCH

(purchase separately)

SWITCH BOX

120 VAC

LINE IN

WHITE

GROUND

(bare)

POWER

SWITCH

WIRING

PLATE

LIGHT

SWITCH

RED

JUNCTION BOX

SWITCH BOX

OFF

L

BLUE

External timer can be used in conjunction with

single-speed mode only, please contact Delta Breez

customer service and consult with a licensed

electrician for compatibility.

Roof cap

(with built-in

damper)

Seal gap

around

housing

Caulk termination

to duct

Fan housing

Short piece of flexible

duct helps alignment

and absorbs

sound

or

Wall cap

(with built-in

damper)

Wall cap

(with built-in

damper)

Unit is not intended for installation in slanted ceiling.