10

UniX

2

en

GL

ish

handling

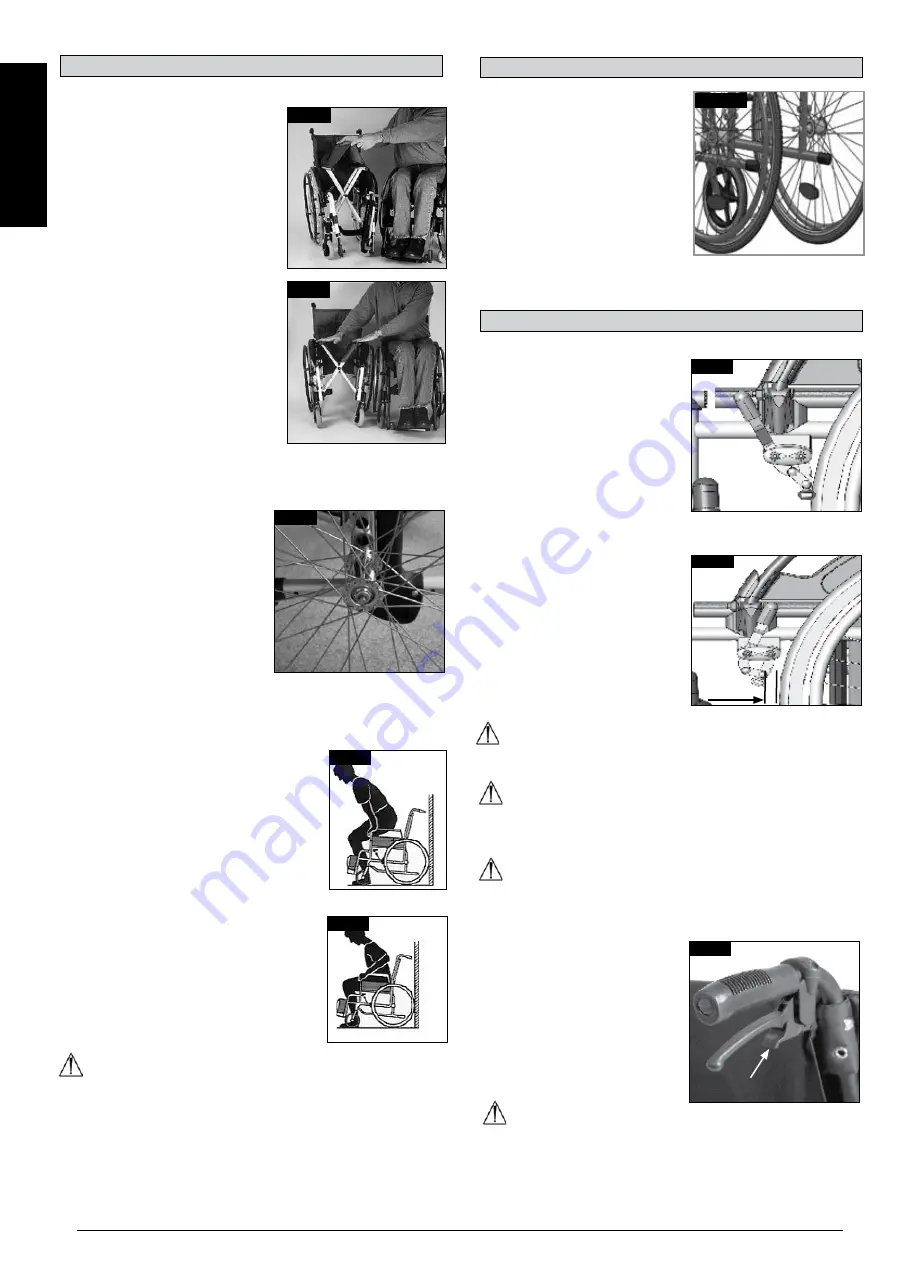

foLDinG up

First remove the seat cushion and

the back seat shell from the

wheelchair and flip up the (platform)

footplate or the individual footrests.

Take hold of the sling or the seat

tubes in the middle, from the back

and pull upwards. The wheelchair will

then fold up. To fold your wheelchair

so that it is as small as possible, e.g.,

to put into a car, you can remove the

footrests (depending on the model).

For this purpose, open the latch from

the outside and swing the footrest to

the side. Then the footrest only has

to be drawn out of the receiver tube

(Fig. 1).

unfoLDinG

Press down on the seat tube (see

figure). Your wheelchair is then

unfolded. Now snap the seat tubing

into position in the seat saddle. This

can be facilitated by slightly tipping

your wheelchair, as this means that

the weight is taken off one of the rear

wheels.

be careful not to get your fingers caught in the cross-

tube assembly

. Refit the seat cushionl (Fig. 2).

Fig. 1

Fig. 2

GettInG Into your wheelchaIr

InDepenDently (fIG. 3)

• The wheelchair should be pushed up against

a wall or solid piece of furniture;

• The brakes should be on;

• The footplates should be hinged up;

• The user can then lower himself into the chair;

• The footplates should then be pushed down

and the feet rested on them in front of the heel

loops.

GettInG out of your wheelchaIr

InDepenDently (fIG. 4)

• The brakes should be on;

• The hinged footplates should be hinged up;

• With one hand on each armrest, the person

should bend slightly forward to bring the body

weight to the front of the seat, and with both

feet firmly on the ground, one foot well back,

push up into the upright position.

warninG!

When standing, do not stand on the footplates or the wheelchair will

tip up. It is easier and safer to get into your wheel chair if you turn

the footplates up and out of the way or take them off the wheelchair.

Fig. 3

Fig. 4

options - brakes

caution!

Mounting the wheel lock too close towards the wheel will

result in a higher effort to operate. this might cause the brake

lever to break!

caution!

Leaning onto the brake lever while transferring will cause the

lever to break! splashing water from tyres might cause the

wheel lock to malfunction..

DruM braKes

Drum brakes permit safe and

convenient braking for an attendant.

They can also be set with the aid of

a locking lever (1) to prevent rolling.

The lever must snap audibly into

place. Drum brakes are not

influenced by air pressure inside the

tyres. Your wheelchair cannot be

moved when the drum brakes are

set (Fig.8).

caution!

Drum brakes must only be adjusted by authorised dealers.

Fig. 8

1

wheeL LocKs

Your wheelchair is equipped with two

wheel locks. They are applied

directly against the tyres. To engage,

press both brake levers forward

against the stops. To release the

locks, pull the levers back to their

original positions.

Braking power will decrease with:

• Worn tyre tread

• Tyre pressure that is too low

• Wet tyres

• Improperly adjusted wheel locks

The wheel locks have not been

designed to be used as brakes for a

moving wheelchair. The wheel locks

should therefore never be used to

brake a moving wheelchair. Always

use the hand-rims for braking. Make

sure that the gap between the tyres

and wheel locks complies with given

specifications. To readjust, loosen

the screw and set the appropriate

gap. Then re-tighten the screw (Fig.

6 + 7).

caution!

After each adjustment of the rear wheels, check the wheel lock gap

and re-adjust if necessary.

Fig. 6

options - step tubes

step tubes

(FIG.5)

Step tubes are used by attendants to

tip a wheelchair over an obstacle.

Simply step on the tube to push a

wheel chair, for example, over a kerb

or step.

note:

Sunrise Medical strongly

reccommends the use of a step tube

on any model where attendant use is

the predominant intended use.

Damage to the backposts may occur

if you constantly use the backpost without a step tube, as a lever to

pull back on to tip the wheelchair, in order to overcome obstacles.

Fig.5

Fig. 7

20mm

Quick-release axles on rear wheel

The rear wheels are equipped with

quick-release axles. The wheels can

thus be fitted or removed without

using tools. To remove a wheel,

simply depress the quick-release

button on the axle (1) and pull the

wheel off the axle (Fig. 3).

caution:

hold the quick-release button on

the axle depressed when inserting

fig. 3

the axle into the frame to mount the rear wheels. release the

button to lock the wheel in place. the quick-release button

should snap back to its original position.