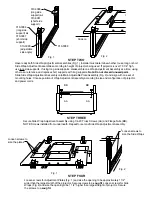

Fig. 2

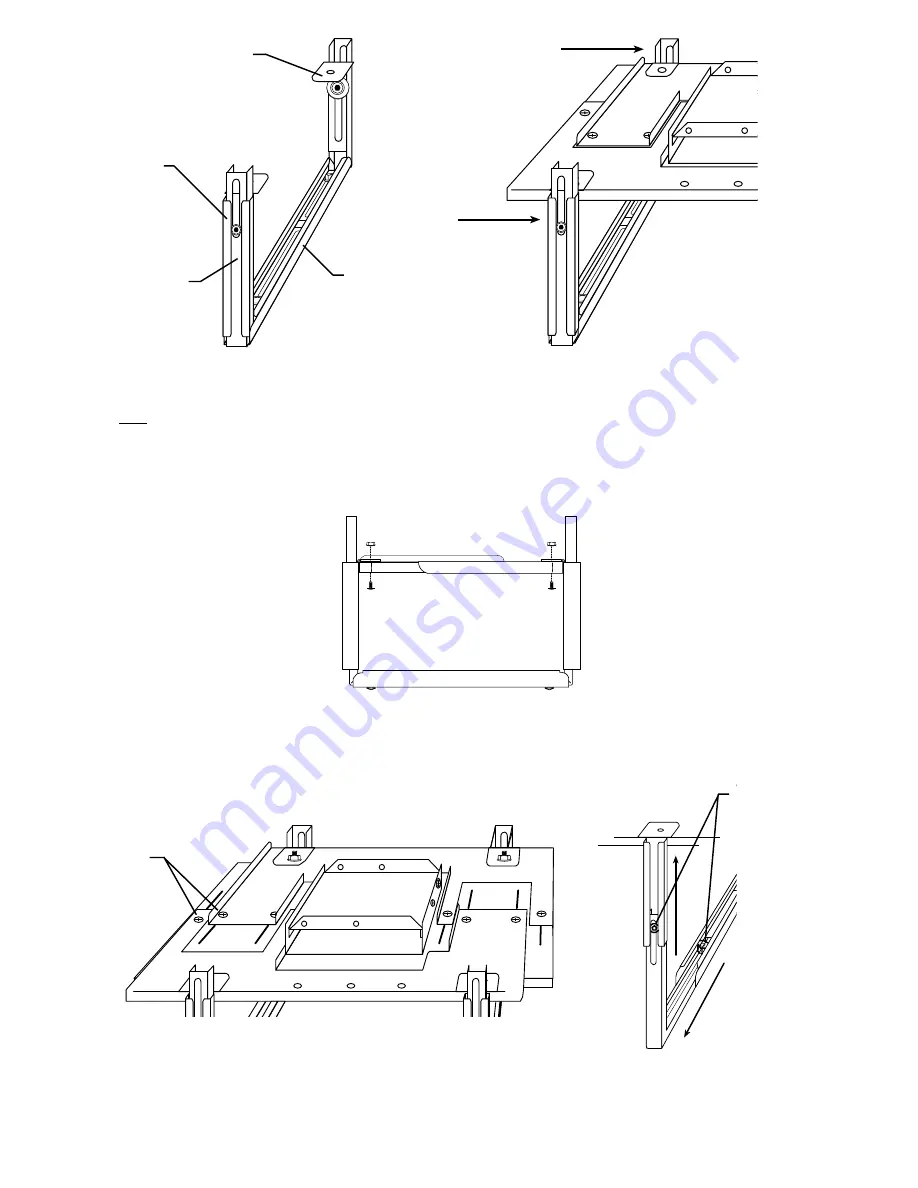

STEP THREE

Secure Side Wrap Adjustment Assembly using 1/4-20 Truss Screws (AA) and Flange Nuts (BB).

NOTE: Screws installed from underneath. Repeat for second Side Wrap Adjustment Assembly.

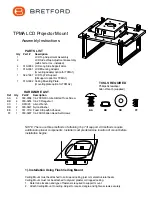

STEP TWO

Have ready both Side Wrap Adjustment Assemblies (Fig. 1). Installer must determine whether to use long or short

Side Wrap Adjustment Assemblies according to height of projector being used. If projector is over 10 1/4" high,

use long side supports. If using long side supports, disassemble one Wrap Adjustment Assembly at a time, using

other as a reference, and replace short supports with long supports.

Note: Do not discard unused parts

.

Slide Side Wrap Adjustment Assembly onto Main Adjustable Plate Assembly (Fig. 2) and align with one set of

mounting holes. Choose position of Wrap Adjustment Assembly according to size and configuration of projector

and power cords.

STEP FOUR

Loosen screws for Adjustment Plates (Fig. 1) and size the opening to be approximately 1 1/2"

wider than the largest width of the projector. Secure screws to a

snug fit

. Loosen screws for Side

Wraps (Fig. 2) and size the opening to be 1 1/2" higher than largest height of projector. Secure

the screws to a

snug fit

.

Fig. 1

Fig. 2

Fig. 1

Slide on

Loosen screws to

size the Side Wraps

AA

BB

Loosen screws to

size the plates

AA

BB

010-3086

(long side

support)

or

010-3087

(short side

support)

010-3088

(adjustable

side angle)

010-3089

010-3086

(long side

support)

or

010-3087

(short side

support)