Summary of Contents for B170 V 250

Page 3: ...31 b170 v CONGRATULATIONS BREVIGLIERI range ...

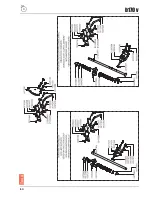

Page 29: ...Tav 1 137 b170 v ...

Page 30: ...Tav 2 b170 v 138 ...

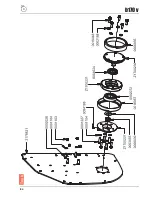

Page 31: ...Tav 3 139 b170 v ...

Page 32: ...Tav 4 b170 v 140 ...

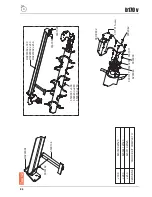

Page 33: ...Tav 5 Z0100131 3177557 8064512 8064556 0050166 8064533 141 b170 v ...

Page 35: ...Tav 7 Z1700155 143 b170 v ...

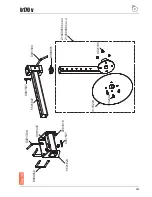

Page 36: ...Tav 8 b170 v 144 ...

Page 42: ...Tav 14 0020675 E1200165 E1200165 E1200165 0001020 0001019 0005505 b170 v 150 ...

Page 44: ...Tav 16 b170 v 152 ...

Page 46: ......

Page 47: ......

Page 48: ......