macchine agricole

- 30 -

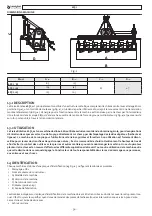

b

25

f

SECTION 5

Maintenance

5.1 ROUTINE MAINTENANCE

The various routine maintenance operations are described below. Remember that lower running costs and long machine life

depend on continual compliance with these instructions.

WARNING

Before proceeding with any operation, make sure that the machine is parked on a flat surface. Prevent it from moving by

placing chocks under the wheels.

Servicing, adjusting and the operations required to prepare the machine for work must be carried out with the tractor and

the driveline detached from the machine.

The servicing frequencies indicated in this manual are indicative and refer to normal conditions of use. They may therefore vary

depending on the type of service, whether the environment is dirty or not, seasonal factors, etc.

The servicing operations must obviously be carried out more frequently in heavier duty service conditions.

CAUTION

Before injecting lubricating grease into the grease nipples, carefully clean the unions to prevent mud, dust or foreign bodies

from mixing with the grease as this would reduce or even annul its lubricating effects.

Injection into the greasing points of a large quantity of grease at high pressure can damage the bearing protection.

This operation must therefore be carried out with due care.

Lubricate and grease all the required points.

Use oil of the recommended type for topping up and changes.

DANGER

Keep all lubricants well away from children’s reach.

Carefully read the warnings and precautions on the lubricant containers.

The operator should thoroughly wash himself after using lubricants.

Dispose of used oil in compliance with the anti-pollution laws.

5.2 LUBRICATION

Lubrication of any machine with parts that turn and/or rub together is a vitally important task for the life and functionality of the

actual machine itself. Lubrication must therefore be carried out systematically and at the required intervals. The frequencies given

refer to machine use in a normal environment. If this machine is used in heavier duty conditions, it must naturally be lubricated

more frequently.

5.2.1 RECOMMENDED LUBRICANTS

It is advisable to lubricate the overdrive with: SAE 85W/140 OIL, complying with API-GL5/MIL-L-2105C specifications.

▪

For all greasing points, the Manufacturer recommends: LITHIUM GREASE.

▪

When servicing the driveline, strictly comply with the instructions given by the driveline Manufacturer, in the specific operation

and maintenance manual with which each driveline is equipped.

5.2.2 AFTER THE FIRST 8 HOURS SERVICE

Each new machine must be checked after the first 8 hours service. Proceed in the following way:

Check the general condition of the machine

▪

Make sure that all the screws are well tightened

▪

Check the cutting tools for wear and make sure that the bolts that fasten them are well tightened

▪

Check the level of the lubricants

▪

Summary of Contents for b25f - 125

Page 76: ... 76 b25f macchine agricole ...

Page 78: ...b25f macchine agricole 78 Tav 1 ...

Page 80: ...b25f macchine agricole 80 Tav 2 ...

Page 82: ...b25f macchine agricole 82 Tav 3 ...

Page 84: ...b25f macchine agricole 84 Tav 4 ...

Page 86: ...b25f macchine agricole 86 Tav 5 ...

Page 88: ...b25f macchine agricole 88 Tav 6 ...

Page 90: ...b25f macchine agricole 90 ...

Page 91: ...b25f macchine agricole 91 ...