- 30 -

doble - maxi doble

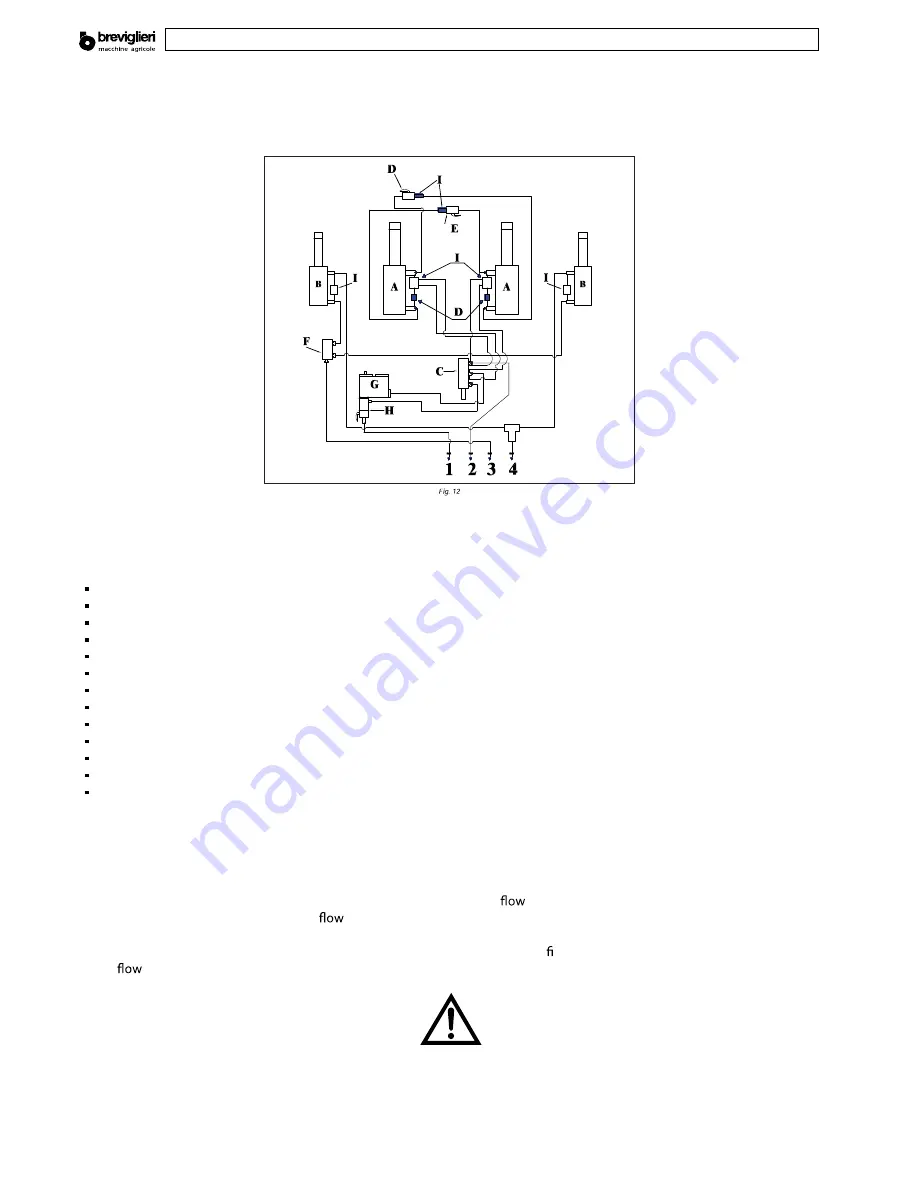

4.5 HYDRAULIC CIRCUIT

d

e

g

a

g

n

e

d

n

a

r

o

t

c

a

r

t

e

h

t

f

o

s

t

n

i

o

p

e

e

r

h

t

e

h

t

o

t

d

e

h

c

ti

h

.

e

.i

,

y

a

w

t

c

e

r

r

o

c

e

h

t

n

i

s

n

o

it

a

r

e

p

o

y

r

a

n

i

m

il

e

r

p

e

h

t

t

u

o

d

e

ir

r

a

c

g

n

i

v

a

h

r

e

t

f

A

e

h

t

w

o

ll

a

o

t

r

e

d

r

o

n

i

r

o

t

c

a

r

t

e

h

t

n

o

s

p

a

t

c

il

u

a

r

d

y

h

e

v

it

a

l

e

r

e

h

t

o

t

d

e

t

c

e

n

n

o

c

e

b

t

s

u

m

t

i

u

c

ri

c

c

il

u

a

r

d

y

h

e

h

t

f

o

s

e

p

i

p

e

h

t

,

e

n

il

e

v

ir

d

e

h

t

various components of the implement to operate.

KEY Fig.12

MAXIMUM PRESSURE 180 Bar

1/4” AND 3/8” HYDRAULIC PIPES

A) Hydraulic cylinders to control steerage hoe

B) Hydraulic cylinders to regulate rollers

C) Hydraulic cylinder to hitch/unhitch steerage hoe

D) Control cylinder speed adjuster valve

E) Floating valve

F) Flow divider

G) Sequence valve

H) Safety valve

I ) Locking valve

1) Harrow closing/harrow hitching oil pipe

2) Harrow opening/harrow unhitching oil pipe

3) Roller lowering oil pipe

4) Roller lifting pipe

4.6 HOEING UNIT OPENING/CLOSING

The two hoeing units are respectively opened during the work phase and closed when the machine is transported on the roads

by a hydraulic control with two cylinders (16 Fig. 1 and 4 Fig. 8). Both hydraulic cylinders are equipped with locking valves (17 Fig.

1). If a hydraulic pipe suddenly bursts, these valves instantly stop the oil

and, consequently, the machine in the position to

which it has set. The cylinders also have a

valve that regulates the opening and closing speeds of the hoeing units (D Fig. 12).

These valves are calibrated so that the movement of the cylinders and, thus, the lowering and lifting movements of the hoeing

t

u

n

r

e

n

i

a

t

e

r

e

h

t

g

n

i

n

e

s

o

o

l

r

o

g

n

i

n

e

t

h

g

it

y

b

d

e

i

d

o

m

e

b

n

a

c

t

n

e

m

e

v

o

m

s

i

h

T

.

e

l

b

i

s

s

o

p

s

a

s

u

o

e

n

e

g

o

m

o

h

d

n

a

h

t

o

o

m

s

s

a

e

r

a

,

s

ti

n

u

of the

governor valve until the two side hoeing units lift and lower in the desired way. After this, lock the valve in position

with the ring nut in the governor valve.

WARNING

When the hoeing units are in the vertical position, check the rear visibility from the driving seat in the tractor as it could be

obstructed with the hoeing units in this condition. In this case, you are advised to mount one or more rear view mirrors on

the tractor in order to ensure unobstructed visibility.

Summary of Contents for DOBLE

Page 19: ...doble maxi doble 37 ...

Page 21: ...doble maxi doble 92 Tav 1 ...

Page 22: ...doble maxi doble 93 ...

Page 24: ...doble maxi doble 95 ...

Page 25: ...doble maxi doble 96 ...

Page 26: ...doble maxi doble 97 Tav 6 ...

Page 27: ...doble maxi doble 98 ...

Page 29: ...doble maxi doble 100 ...

Page 30: ...doble maxi doble 101 ...

Page 31: ...doble maxi doble 102 ...

Page 32: ...doble maxi doble 103 ...

Page 33: ...doble maxi doble 104 ...

Page 34: ...doble maxi doble 105 ...

Page 35: ...doble maxi doble 106 ...

Page 36: ...doble maxi doble 107 ...