Hypermaster XL

- 29 -

A good cut is obtained at a low ground speed and with the blade rotor turning at high speed.

CAUTION

The speed of the tractor when the machine is operation must not exceed 6-8 kph or components could be broken or dama-

ged.

Never swerve sharply or change direction when the machine is working.

Never ever reverse when the machine is on the ground.

DANGER

Stones or other sharp objects may be thrown up by the spinning blades during work. Constantly check to make sure that

there are no bystanders, children or domestic animals within the range of action of the machine.

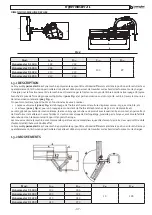

4.1.1 SHREDDING DEGREE ADJUSTMENT

DANGER

Cutting height regulation is a dangerous operation. Wear work gloves and use suitable tools in a good condition.

Proceed in the following way to adjust the cutting height:

Park the tractor on a flat surface and hitch the machine then raise it with the power lift

1.

Place two strong stands at the sides of the machine to protect yourself if it should fall

2.

Lower the machine on to the stands, turn off the tractor engine and apply

3.

the parking brake

The cutting height is established by the position of the bearing roller on the

machine (

Fig. 6

). To change the position, slacken off the bolts (

1 Fig. 6

) on both

sides, then remove them from one side and move the roller either down or up

depending on the required cutting height. Fit the bolts back in place and repeat

the operation on the other side. Now carefully tighten all the bolts. A taller

cutting height is obtained with the roller in the lower position while the cutting

height will be shorter when the roller is higher up. This is because the machine

is furthered or neared from or to the ground. Once the bearing roller has been

adjusted and the machine lowered to the ground, adjust the third point of the

machine so that it is parallel to the ground.

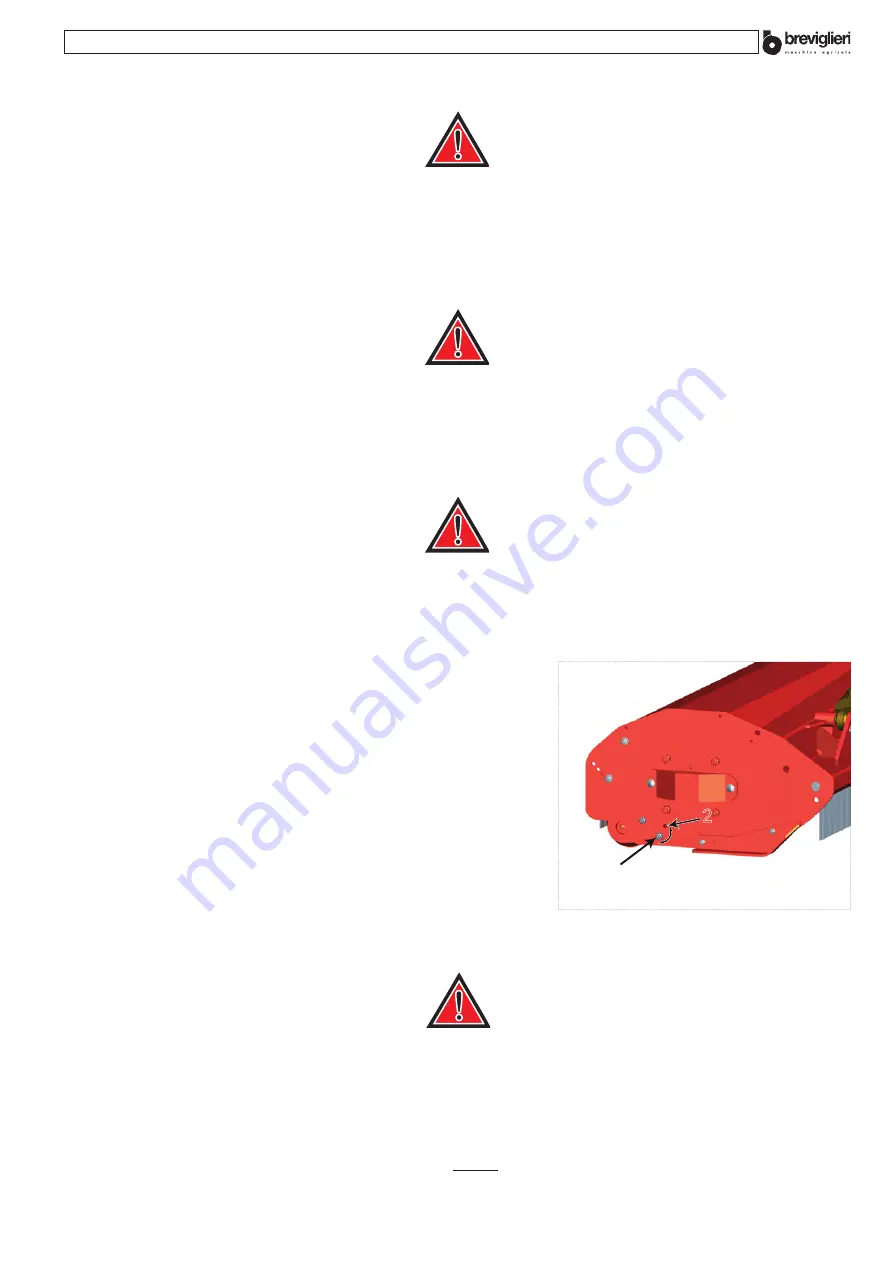

4.2.2 SIDE SHIFT

CAUTION

Operate the movement and pivoting rams with caution to avoid hitting or colliding with unseen objects.

Fit the quick couplings of the hose pipe ends into the relative taps on the tractor in order to operate the pivoting and movement

rams. The tractor needs

2

double-acting control valves (

4 oil taps

) to operate both the rams and the hoses must be fitted in pair

on each control valve. The manoeuvres will be controlled from the tractor, using the levers of the tractor’s hydraulic control valves.

The valve controls must be operated in a gradual way. Do not force the manoeuvre when the ram is in its end of stroke positions

(fully open or fully closed). The maximum operating pressure is

150 bar.

1

2

Fig. 6

Summary of Contents for hurricane h102

Page 84: ...Hypermaster XL macchine agricole 84 Tav 1 ...

Page 86: ...Hypermaster XL macchine agricole 86 Tav 2 ...

Page 88: ...Hypermaster macchine agricole 88 Tav 3 16 15 14 ...

Page 90: ...Hypermaster XL macchine agricole 90 Tav 4 ...

Page 92: ...Hypermaster XL macchine agricole 92 Tav 5 ...

Page 94: ... A P P U N T I N O T E S N O T E A N O T A C I Ó N M E R K M A L E N ...

Page 95: ... A P P U N T I N O T E S N O T E A N O T A C I Ó N M E R K M A L E N ...