- 30 -

W

VU

ground).

Increase the ground speed.

ȡ

Cut plants not shredded enough

Slightly lower the machine towards the ground.

ȡ

Reduce the ground speed.

ȡ

Do not work in soil that is too wet.

ȡ

Make sure that the speed of the tractor’s PTO is correct and at full rate (540 or 1000 rpm, depending on the model)

ȡ

Rotor clogged

Soil too wet to work.

ȡ

Raise the machine from the ground.

ȡ

Reduce the ground speed.

ȡ

Do not work where the grass is too tall. If necessary, remove any material that has built up at the sides of the rotor to pre-

ȡ

vent overheating.

The machine jolts over the ground or vibrates

Foreign bodies locked between the knives.

ȡ

Worn or broken knives.

ȡ

Rotor misshapen owing to blows from foreign bodies received during work.

ȡ

Other faults

The machine fails to work evenly along its width, shredding either too much or too little on one side, for example on the

ȡ

right: shorten the right link.

Work on hilly ground

It is advisable to proceed «upwards» in the direction of the slope. Particular attention should be paid since, owing to the nature of

the ground, the stability of the tractor could be compromised or it could slip sideways.

Winter periods

It is inadvisable to work with the machine during cold periods, when the temperature drops below 0°C (zero degrees centigrade),

because the tines become sensibly more fragile. Moreover, when the weather is cold, the machine must be allowed to idle for a

few minutes with the PTO at half rate so as to allow the lubricants and transmission components to warm up.

4.5 TOOLS

The hammers/knives with which the machine is equipped are suitable for work with soil/plants of normal conformation. Check

their condition each day to make sure they are not worn. If they should accidentally bend (or break) during work, they must be

immediately replaced and mounted in the identical position.

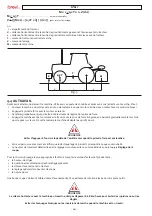

DANGER

Tool replacement (hammers or tines) is a dangerous operation.

Proceed in the following way to replace the tools:

ƪ ǡ

ȡ

then raise the machine with the power lift

Insert two strong bearing stands at the sides of the machine

ȡ

to protect yourself should it fall

ǡơ Ǧ

ȡ

ne and apply the parking brake

The hammers or tines must always be replaced in diametri-

ȡ

cally opposite pairs in order to keep the rotor in a balanced

condition

Proceed as described below to replace worn or broken hammers:

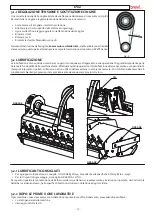

Remove the nut (Fig.

ȡ

7

) of the bolt that fastens the worn

hammer. During the assembly phase, make sure that the new

ƤǢ

Check the bolts and self-locking nuts for wear and replace

ȡ

them if necessary.

Fig. 7