- 34 -

W

VU

Make sure that all the screws are well tightened

ȡ

Check the cutting tools for wear and make sure that the bolts that fasten them are well tightened

ȡ

Check the tension of the belts

ȡ

Check the level of the lubricants

ȡ

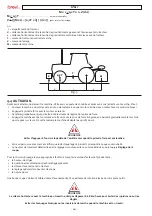

5.2.3 EVERY 20 HOURS SERVICE

Ƥ

ȡ

Grease the driveline

ȡ

5.2.4 EVERY 100 HOURS SERVICE

Ǥ ǡǤ

5.2.5 EVERY 500 HOURS SERVICE

Change the oil in the overdrive housing after every 500 hours service or at least once a year.

5.3 PREPARING FOR STORAGE

Proceed with the following operations at the end of the season or if the machine is to remain idle for a long period of time:

Wash all fertilizers and chemical products from the machine and dry it

ȡ

Carefully check the machine and replace any damaged or worn parts

ȡ

ǡ Ƥ

ȡ

Throughly grease the machine and then cover it with a tarpaulin and store it in a dry place. If these operations are carried

ȡ

out with care, it will be all to the user’s advantage as the machine will be in optimum conditions when needed again.

If these operations are carried out with care, it will be all to the user’s advantage as the machine will be in optimum conditions

when needed again. If the machine must be dismantled, comply with the anti-pollution laws in force. Old lubricants must

ơ Ǥ

5.4 SPARE PARTS

All the parts forming the machine can be ordered from the Manufacturer, specifying:

Machine model

ȡ

The serial number of the machine

ȡ

The year of manufacture

ȡ

The serial number of the required part (indicated in the spare parts catalogue), a description of the part and the required

ȡ

quantity

The means of transport

ȡ

Transport way:

if this is not

Ƥǡ

the Manufacturer will dedicate particular care to the service but shall not be liable for delays

in shipment due to unforeseen circumstances. The shipping costs are always at the consignee’s charge. The goods travel at the

purchaser’s risk and peril even when sold carriage paid.

Remember that the Manufacturer is always at your disposal for any assistance and/or spare parts you may required.