Addendum to Installation Instructions – Treadwall

®

units

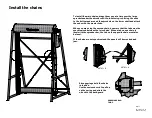

Lower Shaft set screws:

One sprocket on the lower shafts has no set screw: it is located on the left side. This sprocket

does not require a set screw - it is self-aligning and will be aligned when the first panel is

installed.

Rough Initial Operation:

There may be air trapped in the hydraulic oil after transport: this will cause the unit to run quite

rough (cavitation) until the air is slowly released into the reservoir. The amount of air trapped

varies, but it may take 10-15 minutes or more of use to begin smoothing out. The system will

get smoother and smoother with use. This is a normal process.