47

Treadwall M6 Pro Owner’s Manual—2017

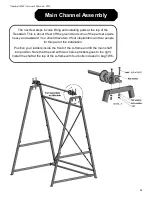

Main Channel Assembly

Before installing the final panel, inspect the inside of the

Treadwall:

1)

There may be air trapped in the hydraulic oil after transport: this will cause the

unit to run quite rough (cavitation) until the air is slowly released into the reservoir.

The amount of air trapped varies, but it may take 10-15 minutes or more of use to

begin smoothing out. The system will get smoother and smoother over time.

2) Make sure the timer-counter is working properly. If it does not count feet as the wall is

moving, check that the magnets and sensor are properly installed and adjusted

3) Check the auto-stop function. Start climbing at a moderate speed. If you stop moving

up, the wall should continue down and stop moving downward when your foot reaches

the bottom of the wall and triggers the micro switch at the bottom of the right channel.

Do this test at all the angles. The micro switch is pre-set at the factory, but it can be

adjusted for sensitivity if required by loosening its small mounting screws and pivoting

it.

4) Check the drive chain at the top of the right channel. The slack should be adjusted

out of it, but it should not be too tight. After climbing for a few minutes, some slack

might develop which should be adjusted out. This chain will stretch over time, and

should be adjusted after about a month of service. There is an inspection hole in the

channel to check the chain so that a climbing panel will not have to be removed.

5) Check the x-bracing rods inside of the channels. They should be equally adjusted

(the turnbuckles should look the same) and finger tight with the lock-nuts tightened

securely. The plastic tubing cushions the x-bracing from the adjuster pipe and spacer

bar to prevent noise. Make sure they are properly adjusted.

6) Check that the chains are properly synchronized. The climbing panels must be

parallel to the spacer bar. If the panels droop down on one side or the other, the

chains are out of sync. We have an easy way of fixing this, so give us a call (800-707-

Final Tests

Summary of Contents for Treadwall M6 Pro

Page 2: ......

Page 4: ...ii Treadwall M6 Pro Owner s Manual 2017...

Page 6: ...2 Treadwall M6 Pro Owner s Manual 2017...

Page 8: ...4 Treadwall M6 Pro Owner s Manual 2017...

Page 14: ...10 Treadwall M6 Pro Owner s Manual 2017...

Page 16: ...12 Treadwall M6 Pro Owner s Manual 2017...

Page 50: ...46 Treadwall M6 Pro Owner s Manual 2017...