24

Treadwall®FT Owner’s Manual—2019

Rev Aug 2019

Assemble frames: Attach horizontals p 26

Place alignment strap p26

Left channel p 28

Right channel p 28

Top shaft p 29

Top Shroud p 30

Bottom shaft p 31

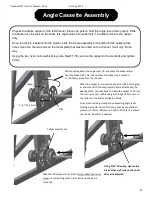

Angle Cassette p 32

Spacer bar p 33

Internal X-bracing p 33

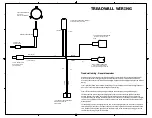

Wiring harness p 34

Remove covers off channels ((1) hydraulic box and (2) bottom access covers) p 33

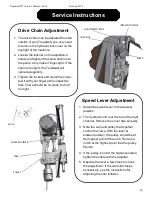

Install drive chain – initial tension p 35

Install top half main chains p 36

Rotate wall up to vertical p 36

Attach angle cassettes and cables p 37

Mount rear guard p 38

Attach bottom half main chain p 38

Mount angle dampener cylinder p 39

Mount counter weights on rear guard p 39

Main chain springs p 40

Align frame and channels to match swing of angle cassettes p 40

Panel Stiffeners p 41

Attach first 1 or 2 panels p 41

Testing p 42

Auto stop

Counter

Alignment interior x-bracing

Alignment exterior x-bracing

Test angle – cassette alignment again

Attach remaining panels except last one p 43

Install bottom side covers – test angle swing again p 44

Mount (optional) Ladder line set p 45

Mount Green holds p 46

Test climb 100 feet/30 meters

Final check Pp 47

Angle brake locking – adjust caliper if needed.

Check drive chain tension again

Auto stop

Mount last panel, hydraulic box cover & access covers p 48

Place mats P 48

Set remaining holds and test climb looking for loose holds

Perform any customer training needed

Warranty p 49

Assembly Checklist

Hint:

Have someone assembling the

panels and stiffeners while oth-

ers are building up the frame

and channels. (p 41)

Summary of Contents for TREADWALL Max Frame

Page 2: ......