6

Assembly

Tube & Ba

ffl

e Assembly

Hardware Installation

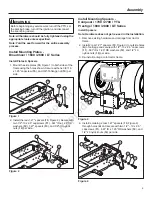

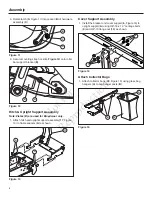

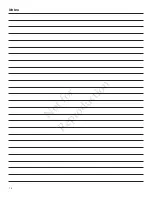

1. On the left side of discharge opening, insert 1/4”-

20x1.25” carriage bolt (

18

, Figure 5) through inside of

mower deck and secure with 1/4”-20 conical nut (

19

) as

shown.

18

19

Figure 5

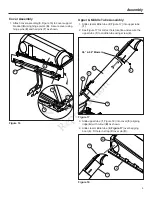

2. On the right side of discharge opening, insert 5/16”-18

x 1.25” carriage bolt (

24

, Figure 6) through the hole

closest to the discharge opening from the inside of

mower deck.

3. On the outside of mower deck, secure with .341” ID x

1.00” OD washer (

23

), single step spacer (

22

), .33” ID x

1.25” OD washer (

21

) and secure with 5/16”-18 flange

nylock nut (

20

).

22

24

21

23

20

Figure 6

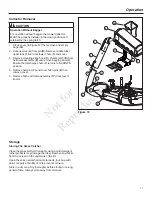

Install Ba

ffl

e

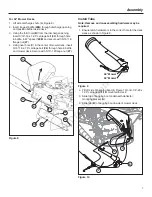

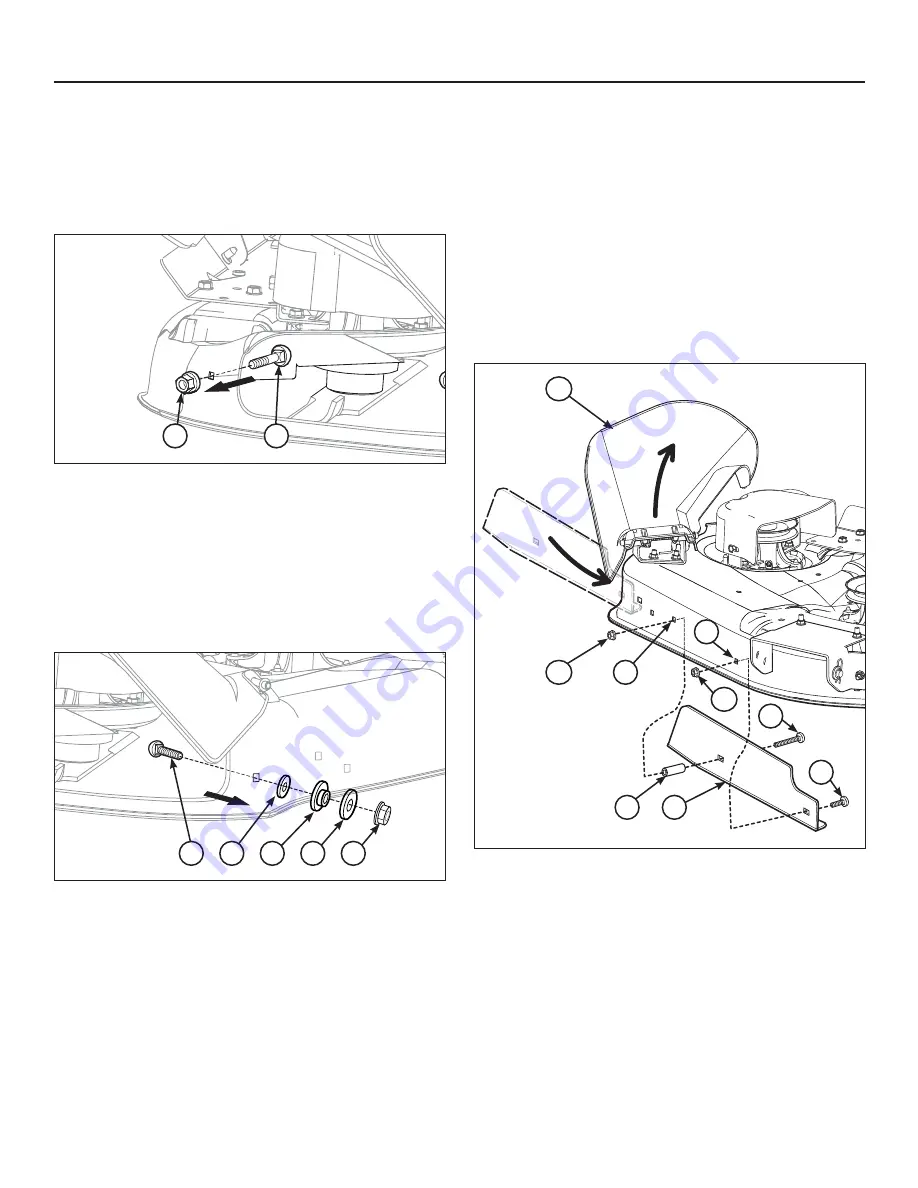

For 46” Mower Decks

1. Lift side discharge chute (

A

, Figure 7).

2. Insert shortest baffle (

28A

) through discharge opening

and position baffle inside deck.

3. Using third hole (

B

) closest to discharge opening, insert

5/16”-18 x 2.0” carriage bolt (

25

) through hole in baffle,

1.32” spacer (

29A

) and secure with 5/16”-18 flange nut

(

27

).

4. Using hole (

C

) near the center of mower deck, insert

5/16”-18 x .75” carriage bolt (

26

) through hole in baffle,

and mower deck. Secure with 5/16”-18 flange nut (

27

).

28A

29A

A

27

25

B

26

C

27

Figure 7

No

t fo

r

Rep

rod

uct

ion