15

Air Compressor Maintenance

Maintenance consists of keeping the air compressor clean.

Store the unit in a clean dry environment where it will not be

exposed to excessive dust, dirt, moisture or any corrosive

vapors. Cooling air slots in the air compressors engine must

not become clogged with dirt, leaves or any other foreign

material.

NOTE:

DO NOT use a garden hose to clean air compressors

engine. Water can enter engine fuel system and cause

problems.

Cleaning Unit

Keep your air compressor clean and dry by placing it in a

location far away from sources of contamination. Make sure

the unit is kept in a well-ventilated area. Protect hoses,

connectors, quick connects, and accessories from damage.

To prolong compressor life, perform these steps weekly. If

the operating environment is particularly dirty, perform daily.

IMPORTANT

: DO NOT use jets of water or flammable liquids

to clean unit.

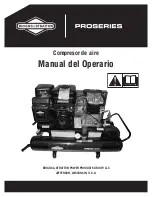

1. With spark plug disconnected, use a soft cloth and a

small brush for cleaning accumulated dirt and debris

from the following locations:

•

Cooling fins on top and sides of air compressor

pump, and engine blower housing slots (

A

).

•

Oil fill locations and adjacent areas on both air

compressor pump housing and engine

•

Oil drain plugs and adjacent areas on both air

compressor pump housing and engine

•

Pressure control knob, gauges, quick connect

fitting, drain valves and safety valve

•

Engine switch and adjacent area

•

Choke lever, engine speed lever, fuel valve lever and

adjacent area on carburetor

•

Spark plug and adjacent area

•

Idle control valve and toggle

•

Fuel tank cap and adjacent area

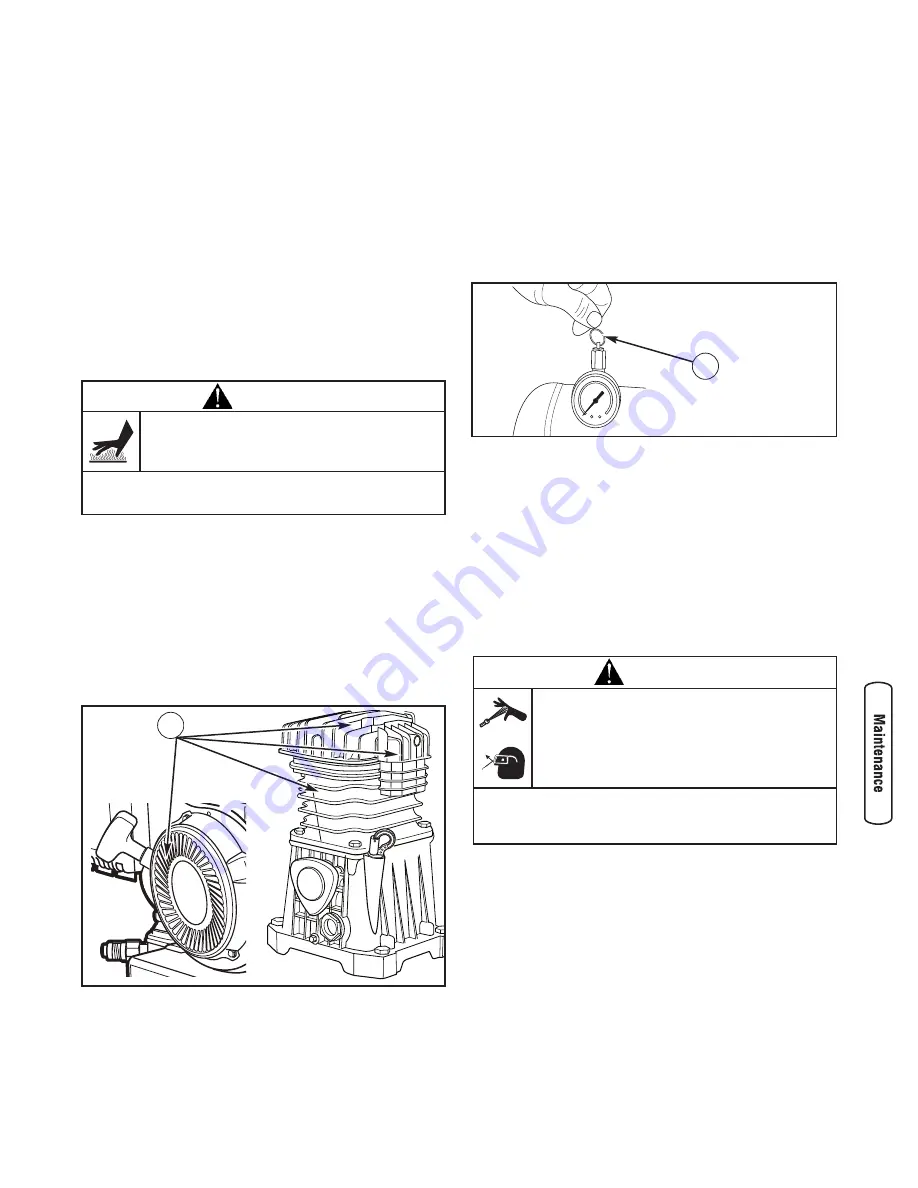

Inspect Safety Valve

1. Pull ring on safety valve (

B

) and observe that safety

valve operates freely.

2. If valve is stuck or does not operate smoothly, it must

be replaced with same type of valve. Take unit to

authorized service facility for repair.

Inspect Quick Connect Fittings and Tank Drain Valves

1. Turn off your air compressor as described in

Stopping

your air compressor

.

2. Disconnect air tool or accessory from unit. Inspect

quick connect fittings for damage and clean.

3. Pull ring on safety valve to reduce air pressure. Release

safety valve ring.

4. Open both drain valves (turn fully counterclockwise)

and permit accumulated water to be discharged. Valves

should operate smoothly and have full range of

operation.

5. After water has drained, close drain valves fully

clockwise.

NOTE

: If drain valves are plugged, pull safety valve ring to

fully drain air from tanks. Remove, clean and reinstall drain

valves using pipe thread sealant.

WARNING

Operating air compressor and tubing are HOT

and can cause burns.

• DO NOT touch compressor or tubing.

• Allow compressor to cool before servicing.

A

B

WARNING

Compressed air stream from hose or tank drain

can cause soft tissue damage to exposed skin

and can propel objects leading to severe injury

and / or property damage.

• DO NOT direct air stream at self or others.

• Always wear ANSI Z87.1 approved safety glasses with side

shields.