16

BRIGGSandSTRATTON.COM

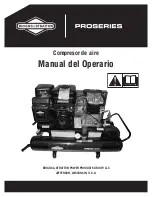

Pump Oil

Checking Pump Oil Level

Use these steps to check oil level:

1. Turn off your air compressor as described in

Stopping

your air compressor

.

2. Place unit on a flat, level surface.

3. Carefully observe sight glass and verify that oil level is

at the dot (

D

) in the center of the sight glass.

4. If pump oil level is too low, slowly add recommended

oil into oil fill (

B

) to proper level. If oil is above

MAXIMUM oil level (

C

), drain excess oil, as described

in next section.

Changing Pump Oil

At recommended oil change interval, follow these steps:

1. Turn off your air compressor as described in

Stopping

your air compressor

.

2. Place unit on a flat, level surface.

3. Remove oil breather cap (

A

) from oil fill (

B

) location.

4. Position a suitable container under drain plug (

E

) to

collect drain oil.

5. Use an adjustable wrench to remove hex head drain

plug.

6. Fully drain oil into container. Install drain plug and

tighten using adjustable wrench. Dispose of used oil

properly.

7. Using oil funnel, slowly add recommended oil. Visually

inspect oil level frequently at sight glass to avoid

overfilling air compressor pump.

8. When oil is at proper level, reinstall oil breather cap and

wipe up any spilled oil.

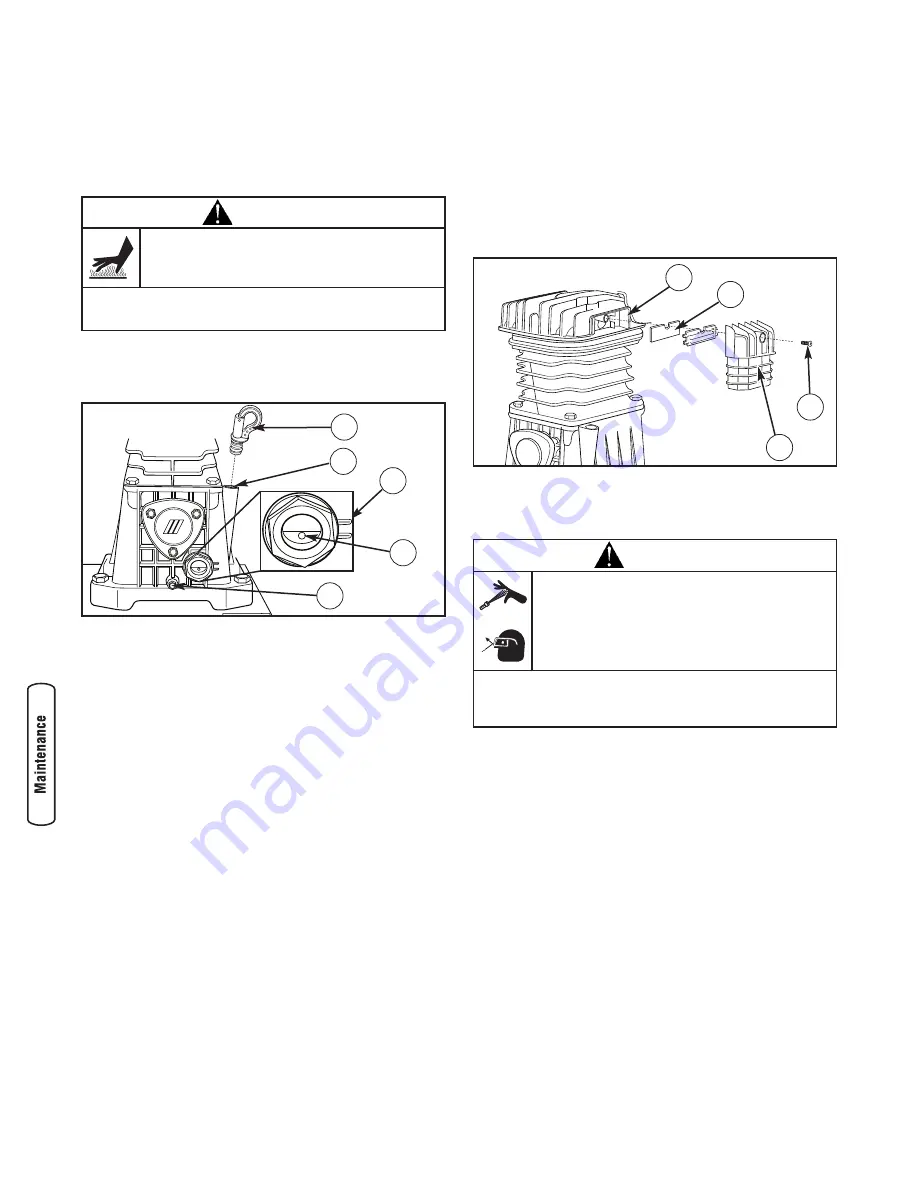

Inspect / Clean Pump Air Filter

Use the following steps to check and clean the compressor’s

internal air filter.

1. With air tank fully pressurized, turn off your air

compressor as described in

Stopping your air

compressor

.

2. Use phillips screwdriver to remove screw (

F

) holding

air filter cover (

G

) on compressor housing (

H

). Remove

air filter cover.

3. Remove air filter media (

J

).

IMPORTANT

: DO NOT operate compressor with air filter

media removed.

4. If dirty, use compressed air to dislodge dirt from air

filter media. Also, blow debris out of air filter cover and

compressor filter housing.

NOTE:

DO NOT use liquid solvents to clean filter media.

5. Replace air filter media in compressor filter housing.

6. Position air filter cover over air filter media. Use phillips

screwdriver to secure cover with screw.

NOTE

: Replace air filter media if it is extremely dirty.

Inspect Safety Labels

As often as desired or at least yearly, inspect all labels

applied to the air compressor. All safety labels should be

present and readable. If any safety label is missing or

illegible, obtain a replacement from an authorized service

center or call the air compressor helpline at

(800) 743-4115

.

WARNING

Compressed air stream from hose or tank drain

can cause soft tissue damage to exposed skin

and can propel objects leading to severe injury

and / or property damage.

• DO NOT direct air stream at self or others.

• Always wear ANSI Z87.1 approved safety glasses with side

shields.

F

G

H

J

WARNING

Operating air compressor and tubing are HOT

and can cause burns.

• DO NOT touch compressor or tubing.

• Allow compressor to cool before servicing.

A

B

C

D

E