Not for

Reproduction

30

www.SnapperPro.com

Maintenance

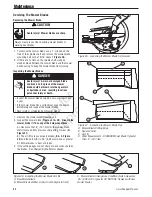

Inspect Muffler and Spark Arrester

Inspect the muffler for cracks, corrosion, or other damage.

Remove the spark arrester, if equipped, and inspect

for damage or carbon blockage. If replacement parts

are required, make sure to use only original equipment

replacement parts.

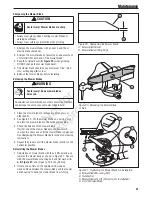

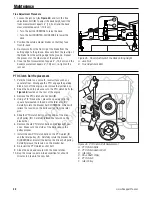

Engine Maintenance

Refer to the engine owner’s manual for all engine

maintenance procedures and recommendations.

WARNING

Replacement parts must be the same and installed in the

same position as the original parts or fire could result.

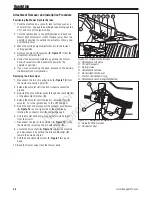

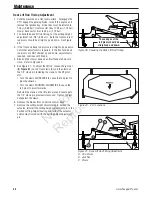

Figure 20. Front Caster & Wheel

A. 1/4-28 Bolt

A

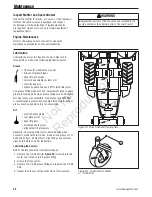

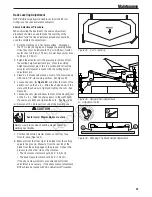

Lubrication

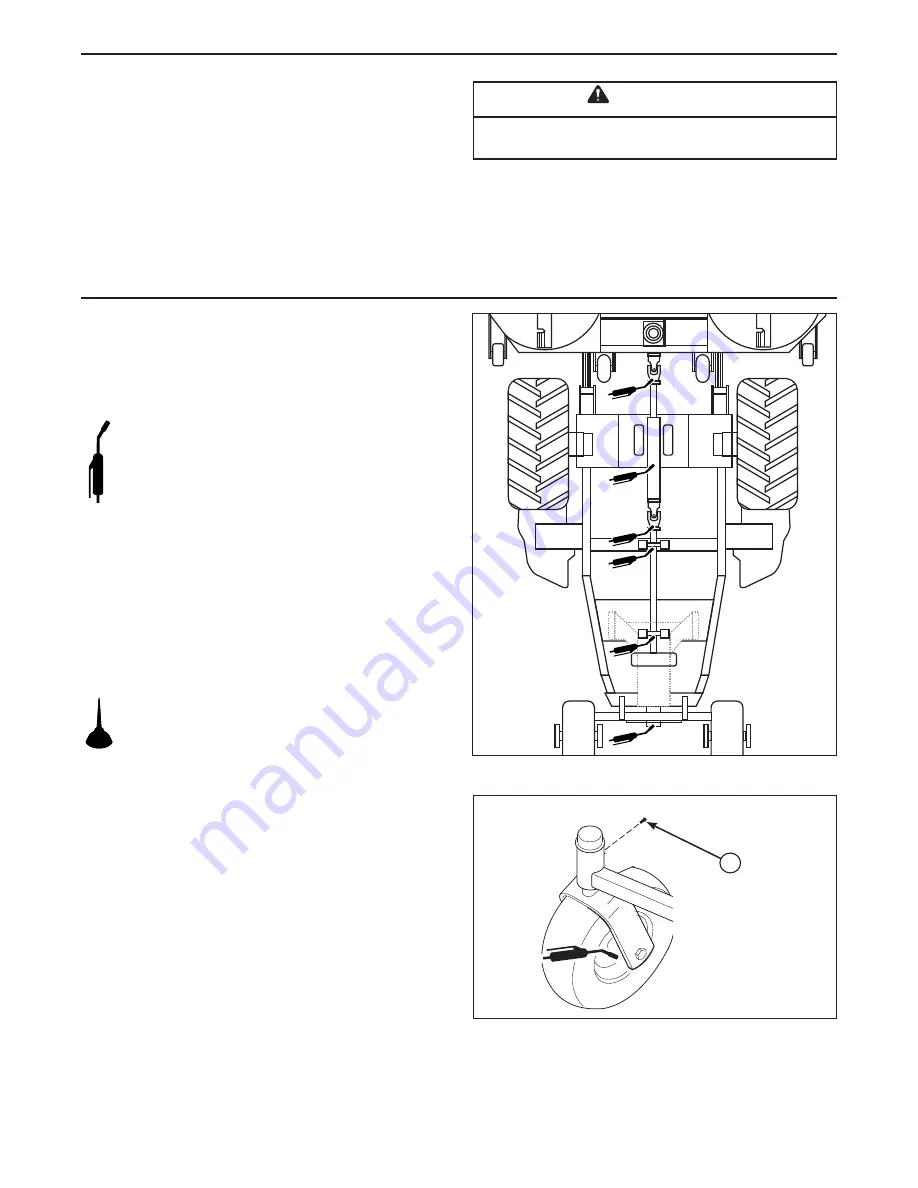

Lubricate the unit at the location shown in Figures 19

through 25 as well as the following lubrication points:

Grease:

• front caster wheel axles & yokes

• drive shaft pillow blocks

• deck lift pivot blocks

• mower deck spindles & idler arm

• rear pivoting axle

• hydraulic pump drive and PTO clutch idler arms

Use grease fitting when present. Disassemble parts to apply

grease to moving parts when grease fittings are not installed.

Not all greases are compatible. Red grease (p/n 5022285)

is recommended, automotive-type high temperature, lithium

grease may be used when this is not available.

Oil:

• control handle pivots

• seat plate pivots

• deck lift pivots

• discharge chute pivots

• attachment lift arm pivots

Generally, all moving metal parts should be oiled when

contact is made with other parts. Keep oil and grease off of

belts and pulleys. Remember to wipe fittings and surfaces

clean both before and after lubrication.

Lubricating the Casters:

NOTE: Casters should be lubricated annually.

1. Remove the 1/4-28 bolt (

A, Figure 20

) screwed into the

caster and install a 1/4-28 grease fitting.

2. Grease the front caster.

3. Remove the 1/4-28 grease fitting and reinstall the 1/4-28

bolt.

4. Repeat the process for the other side of the machine.

Figure 19. Drive Shaft and Pivoting Axle