6. To avoid cross-threading, all spray gun parts should

be screwed in hand tight initially. If the parts cannot

easily be turned by hand, be sure that you have the

correct parts, unscrew, realign, and try again. Never

use excessive force in matching parts.

7. Use only accessories identified by the manufacturer

for the specific tool model.

8. When servicing a tool, use only identical replacement

parts and/or authorized parts.

9. Use only lubricants supplied with the tool or specified

by the manufacturer.

10. Maintain spray guns with care. Keep spray guns clean

and oiled for best and safest performance.

11. Store the tool out of reach of children and other

untrained persons when it is idle.

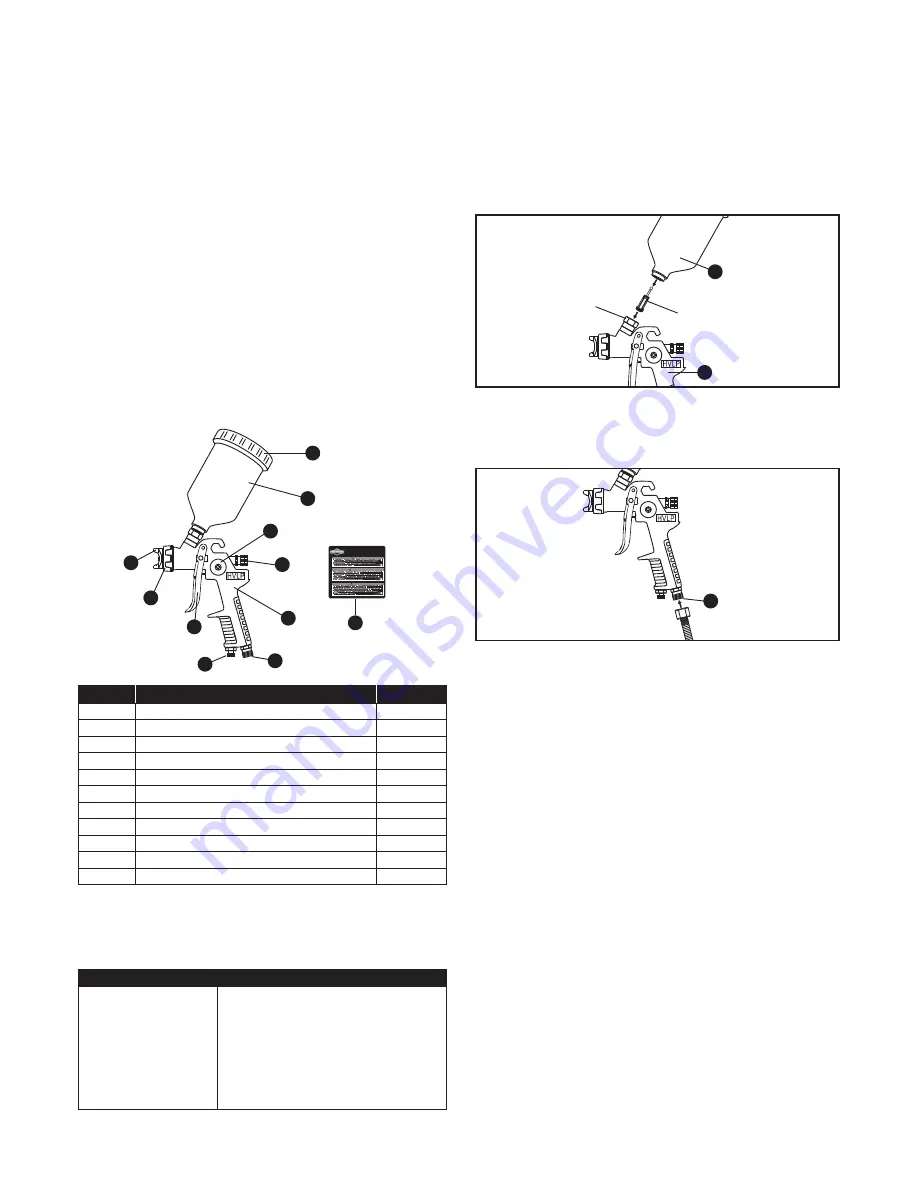

Product Description

A

B

C

D

E

F

G

I

J

H

DESCRIPTION

QUANTITY

PART

H.V.L.P Gravity Spray Gun

Paint Cup

Cup Lid

Air Cap

Air Cap Ring

Spray Pattern Adjustment Knob

Fluid Adjustment Knob

Air Adjustment Knob

Air Inlet

Trigger

Warning Label

1

1

2

1

1

1

1

1

1

1

1

A

B

C

D

E

F

G

H

I

J

K

Technical Specifications

SPECIFICATIONS

COMPONENT

Gravity

1.4 mm

600 ML

30-50 PSI

6.5 CFM

1/4 in. (6.35 mm) 18 NPS

1/4 in. (6.35 mm) (min. inner diameter)

Feed type

Fluid nozzle

Cup capacity

Operating pressure

Air consumption

Air inlet

Air hose

Assembly Instructions

Figure 1

Operation Instructions

A

B

Fluid filter

Fluid inlet

Figure 2

I

4

BRIGGSandSTRATTON.COM

NOTE

The working pressure refers to the air line pressure

when the spray gun trigger (J) is pulled fully under

working conditions.

NOTE

Apply the fluid filter to the fluid inlet of the spray

gun. (See Figure 1)

NOTE

●

Before using desired paint in the spray gun, spray a

compatible thinner or solvent through the gun to remove

any contaminants and residues.

●

Thin paints properly in accordance with the paint manufac-

turer's instructions before spraying. If necessary, carefully

strain the paint through a paint strainer or a piece of

cheesecloth.

●

Fill the paint cup (B) about 3/4 full and start the air

compressor.

●

Set up a piece of cardboard or other scrap material to use

as a target and adjust for best spray pattern.

1. Take out spray gun (A) and put on paint cup (B) with hand.

Make sure that the paint cup (B) is installed with spray gun

(A) tightly and correctly. (See Figure 1)

2. Connect air supply hose (not included) with the air inlet (I)

of spray gun (A). Use seal tape (not included) for airtight

connection. Do not overtighten. (See Figure 2)

3. Set the rated working pressure (i.e. 43 PSI) for best

performance.

DO NOT

exceed spray gun maximum

pressure of 50 PSI.

6388-00

Made in China/Hecho en China/Fabriqué en Chine

NE RETIREZ PAS CETTE ÉTIQUETTE

AVERTISSEMENT

DO NOT REMOVE THIS LABEL

WARNING

NO SAQUE ESTA ETIQUETA

ADVERTENCIA

PISTOLA DE PULVERIZACIÓN DE GRAVEDAD HVLP

H.V.L.P GRAVITY SPRAY GUN

PISTOLET À PEINTURE “GRAVITY” H.V.L.P

K

Not

for

Reproduction