DAILY CLEAN-UP

NOTE

●

Local codes may require specific cleaning methods and

equipments. Follow local codes and manufacturer's

recommendations for the use of disposal of spray paints

and solvent.

●

Clean the spray gun

IMMEDIATELY

after use. Paint and

other materials dry quickly in the small passages inside

the spray gun.

1. Remove and empty paint cup. Rinse with a solvent

recommended for the paint.

3. Remove and check the fluid needle for excessive wear at

the tip and straightness.

NOTE

If the fluid needle tip is worn more on one side than

the other, either the needle is bent or the gun body has been

dropped or knocked out-of-line. There are no adjustments

that can be made to a bent gun body. Test the needle by

rolling on a flat surface. Replace if necessary.

4. Check and replace any damaged gaskets and/or packing

nuts.

5. Unscrew the needle packing seat and replace the needle

packing only if a leak will not stop when the needle

packing seat is tightened. DO NOT overtighten the needle

packing seat because this will restrict movement of the

fluid needle.

6. Reassemble in verse order of the above and use a

non-silicone oil on the moving parts. Apply Vaseline or

light grease on all threaded connections.

2. Refill the paint cup with clean solvent and attach the cup

to the gun body. Spray solvent through the gun into a

container while shaking the spray gun. Once the paint cup

is empty, repeat the process until the solvent comes out

clean. Wipe the gun exterior with a solvent-soaked rag.

3.

Disconnect the spray gun from air supply.

After discon-

necting, point the spray gun into the spent solvent

container and squeeze the trigger again to make sure that

no air remains.

4. Remove the air nozzle and soak in solvent until clean. Use

a small brush for stubborn stains if necessary. Toothpicks

or small brushes may be used to clean air passages.

6. After using water to clean out the spray gun, spray mineral

spirits through the gun to prevent corrosion.

7. Clean and flush gun thoroughly to neutralize any contami-

nants corrosive to the spray gun.

8. Use a non-silicone oil or a light lubricant on all moving

parts when reassembling. Use Vaseline or light grease on

all threaded connections before storage.

PERIODIC CLEAN-UP

NOTE

Due to improper cleaning and/or paint, it may be

necessary to inspect and clean the internal parts and the gun

body.

1. Examine the openings of the air nozzle tip and fluid nozzle

tip. If clogged, remove and soak them in solvent.

2. A brush, toothpick or something similar may be used to

dislodge the dried paint from holes and passages.

5. Clean gaskets with a solvent-soaked rag.

WARNING

Never use metal objects to clean

precisely drilled passages. Damaged passages will

cause improper spraying.

WARNING

Never use metal objects to clean

precisely drilled passages. Damaged passages will

cause improper spraying.

WARNING

Never immerse gaskets or spray gun

body in solvents to prevent damage.

Care and Maintenance

6

BRIGGSandSTRATTON.COM

6-12 in.

Pull

Trigger

Start Stroke

Release

Trigger

End Stroke

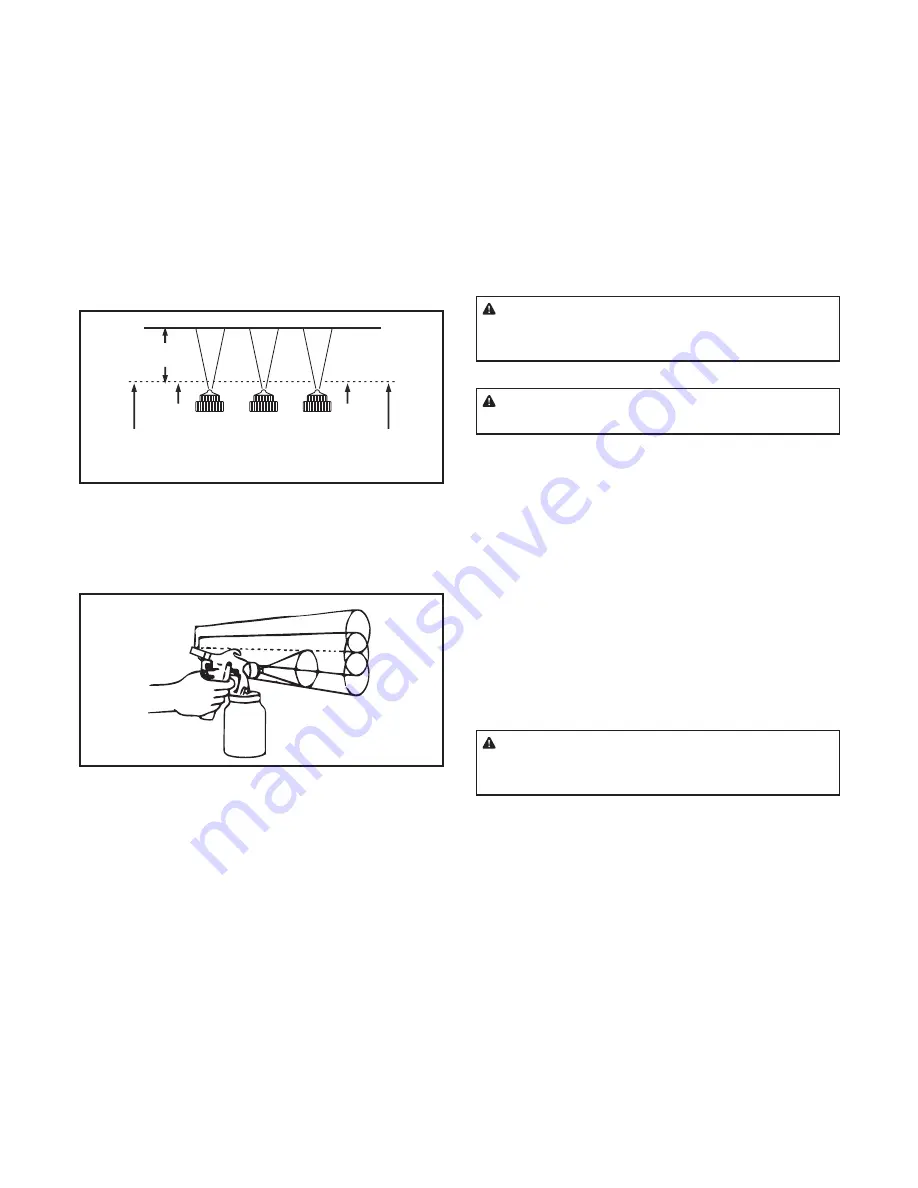

Figure 9

Figure 10

NOTE

The amount of paint being applied can be varied by

the speed of stroke, distance from the workpiece and

adjustment of the fluid adjustment knob (G). If speed of

stroke is too slow, paint will be wet on workpiece and may

run. If speed of stroke is too fast, paint will be dry and

uneven on workpiece.

6. Trigger the gun properly. Start the gun moving at the

beginning of the stroke before squeezing the trigger (J)

and release the trigger (J) before stopping gun movement

at the end of stroke. This procedure will feather/blend each

stroke with the next without showing overlap or uneven-

ness. (See Figure 9)

NOTE

Two thin coats of paint will yield better spraying

results and have less chance of runs than one heavy layer.

7. Overlap strokes just enough to obtain an even and fine

coat. (See Figure 10)

8. Use a piece of cardboard as a shield to catch overspray at

the edges of workpiece and protect other surfaces. Use

masking tape (not included) to cover other areas if needed.

Not

for

Reproduction